Posts Tagged ‘Spindles’

Case Study: Gilman Designs Specialized Spindles for Medical Device Manufacturer’s Blood Centrifuge

Gilman Precision designed and optimized spindles for a leading medical technology manufacturer’s blood centrifuge device, meeting strict design specifications.

Read MoreCase Study: Gilman Optimizes United States Military Tanks With Specialized Spindle Project

Military vehicles have some of the most demanding automotive specifications in the world due to the extreme weather conditions they need to operate in, from -50º F arctic tundras to scorching 120º F deserts. When the U.S. Army encountered issues with their tank engines’ dynamometer jack shaft failing at high temperatures, they turned to Gilman…

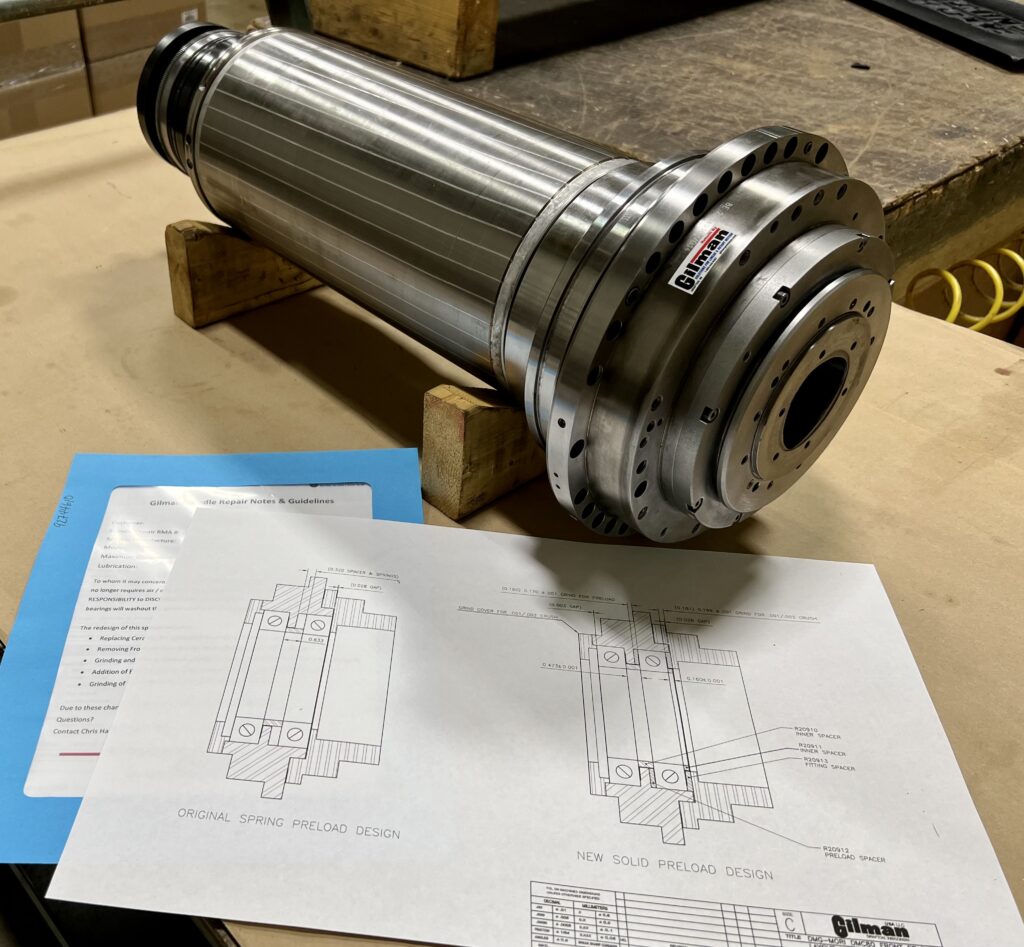

Read MoreSpecialty Metal Forging Company Improves Machine Turning Accuracy with Custom Reengineered Gilman Spindles

When spindles and/or slides are not optimized for specific applications, product quality and machine uptime can suffer resulting in inferior products and productivity. This specialty metal forging company was experiencing a loss in machine accuracy and poor surface finish due to the machining demands being put on the spindle and contacted the skilled professionals at…

Read MoreCase Study: Gilman Provides Solution For Precision Lawn Mower Blade Machining

Manufacturers worldwide rely on Gilman Precision to design solutions for producing products that you use every day. For example, when an OEM manufacturer needed to make a machine that would produce a large amount of lawn mower blades, they chose Gilman Precision to design and build the main slide and spindle components. Designing and Building…

Read MoreA Spindle in Need: Maintenance Tips & Repair to Make Your Broken Part Work Like New

A properly working spindle is an essential part of operations for many companies internationally. Through diligent analysis of the issue and expert repair work, Gilman Precision in Grafton, WI, can make a part work like new. Manufacturers rely on a lot of moving pieces in order to put out the quality products individual companies specialize…

Read More