Specialty Metal Forging Company Improves Machine Turning Accuracy with Custom Reengineered Gilman Spindles

When spindles and/or slides are not optimized for specific applications, product quality and machine uptime can suffer resulting in inferior products and productivity. This specialty metal forging company was experiencing a loss in machine accuracy and poor surface finish due to the machining demands being put on the spindle and contacted the skilled professionals at Gilman for a robust solution.

The forging company has several 5-axis machining centers that are equipped with high-class spring-loaded, ceramic-balled bearings to obtain a milling head spindle rating of 12,000 RPM.

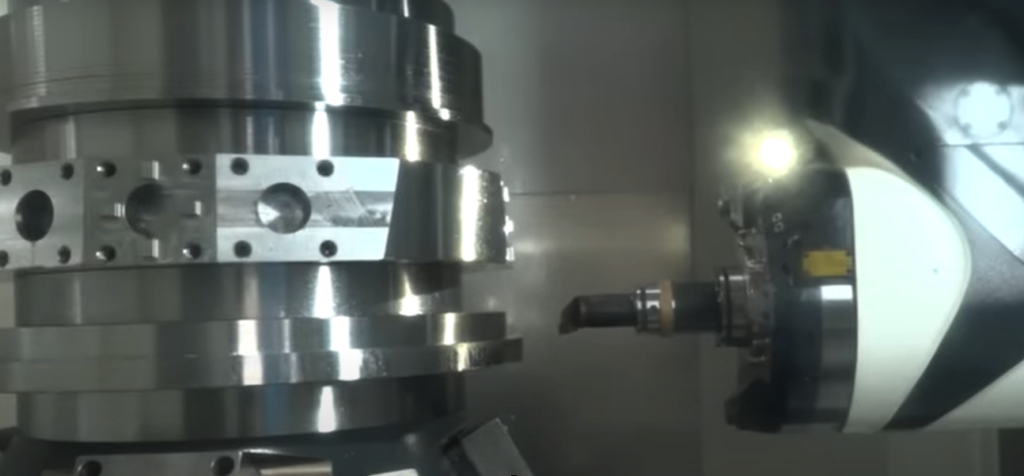

The application calls for the milling head spindle to hold a stationary tool while a table rotates the part, essentially acting as a vertical turning lathe. The demanding machining operation generated forces that damaged the expensive ceramic bearings and resulted in poor surface finish and loss of dimensional accuracy over time.

They looked to Gilman to make the spindle more robust for turning operations, as well as additional suggestions on further improving their machine’s performance.

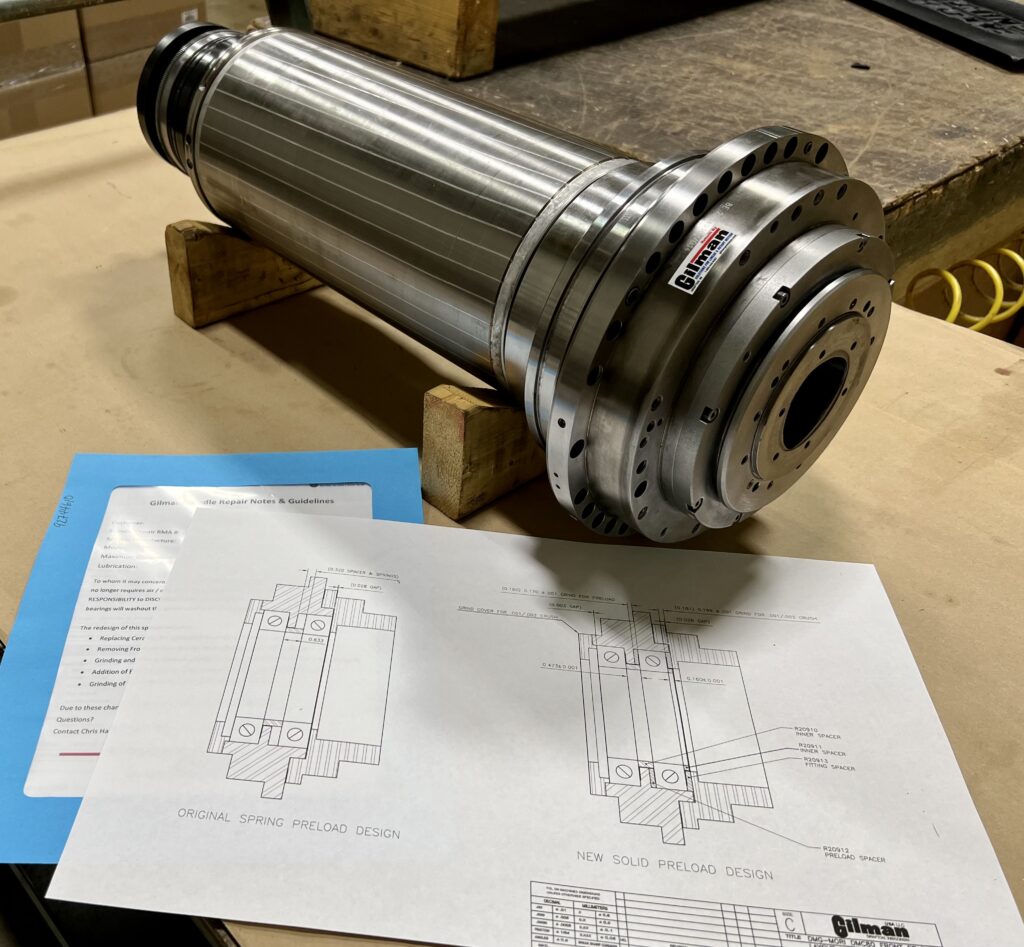

Since higher spindle speeds were not needed, Gilman experts addressed the customer needs by replacing the expensive ceramic bearings with steel-balled angular contact bearings, in addition to changing the lubrication system from an air/oil system to high-pressure, low-RPM grease. Spindle rigidity was also addressed by replacing the spring-loaded bearing arrangement with a solid, heavy preload bearing arrangement and the resizing of the bearing bores. All work was done in-house in Gilman’s temperature-controlled 86,000-square-foot manufacturing and engineering facility

After reengineering the bearing arrangement, fabricating the required components, reassembling the modified spindle, and dynamically testing the spindle, it was shipped back to the customer for installation. The outcome provided a trusted spindle tailored to their specific needs, keeping their machine – and their business – running smoothly.

Looking to Optimize Your Machine’s Performance?

If you have a slide or spindle in need of repair, contact a Gilman technician at 262-377-2434 or sales@gilmanprecision.com.