Gilman Blog

How Gilman Precision Built a Tire Balancing Spindle for the Automotive Industry

A machine integrator within the automotive industry approached Gilman Precision with a unique challenge; they needed to develop a spindle assembly for balancing tires that also required a way to deliver compressed air through the shaft without a typical rotary union. The Gilman team leveraged their expertise in spindle technology to create a solution that…

Gilman Precision Announces New CEO

Gilman Precision, a premier manufacturer of linear and rotary motion solutions, is excited to announce Paul Grekowicz as its new CEO. Under new ownership, Gilman is well-positioned for a dynamic era of growth and technological advancement. Grekowicz joins Gilman Precision with a wealth of experience in strategic leadership roles across multiple B2B manufacturing verticals. His…

Engineering Excellence: Gilman Precision’s Collaboration with Sustainable Vehicle Brand

A sustainable automotive brand known for its cutting-edge technology and innovative electric vehicles was challenged with designing the aluminum front and rear beam structures for the bumper mounts of a new electric car model. The team turned to Gilman Precision for its unparalleled expertise in engineering and customer service. With a legacy of delivering high-quality…

Gilman Precision: A Legacy of Innovation and Customer Service Excellence

Over 70 Years of Excellence Since 1952, Gilman Precision has been dedicated to meeting the needs of diverse projects across all industries—from microchip manufacturers to medical OEMs and the US Military. As business expanded through 1989, a new state-of-the-art facility was built, equipping our mission for exceptional engineering with the highest-quality machinery and skilled engineers. …

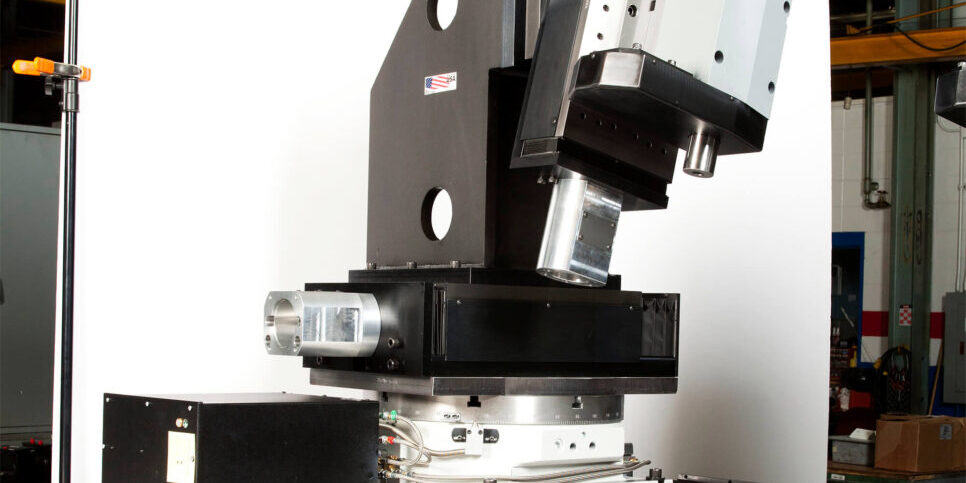

Case Study: Gilman Optimizes F35 Strike Fighter Aircraft Landing Gear with Specialized Five-Axis Machine Module

Manufacturers developing equipment and parts for the US Military are subject to some of the industry’s most demanding engineering specifications and regulations. Knowing these demanding specifications, a US Military Contractor reached out to Gilman’s engineers to create a machine to manufacture components for F35 strike fighter landing gear, which had numerous unique challenges, including the…

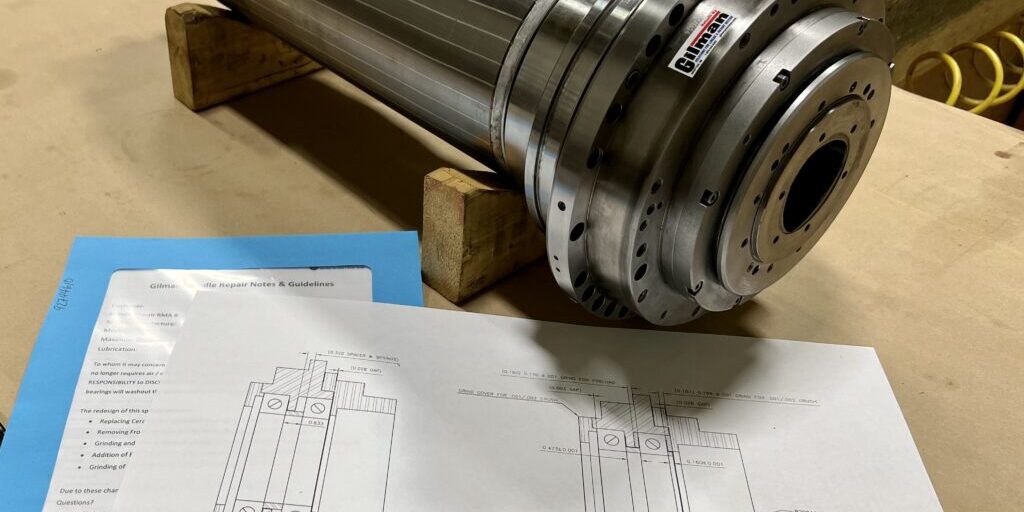

Case Study: Gilman Designs Specialized Spindles for Medical Device Manufacturer’s Blood Centrifuge

Gilman Precision designed and optimized spindles for a leading medical technology manufacturer’s blood centrifuge device, meeting strict design specifications.

Case Study: Gilman Optimizes United States Military Tanks With Specialized Spindle Project

Military vehicles have some of the most demanding automotive specifications in the world due to the extreme weather conditions they need to operate in, from -50º F arctic tundras to scorching 120º F deserts. When the U.S. Army encountered issues with their tank engines’ dynamometer jack shaft failing at high temperatures, they turned to Gilman…

Specialty Metal Forging Company Improves Machine Turning Accuracy with Custom Reengineered Gilman Spindles

When spindles and/or slides are not optimized for specific applications, product quality and machine uptime can suffer resulting in inferior products and productivity. This specialty metal forging company was experiencing a loss in machine accuracy and poor surface finish due to the machining demands being put on the spindle and contacted the skilled professionals at…

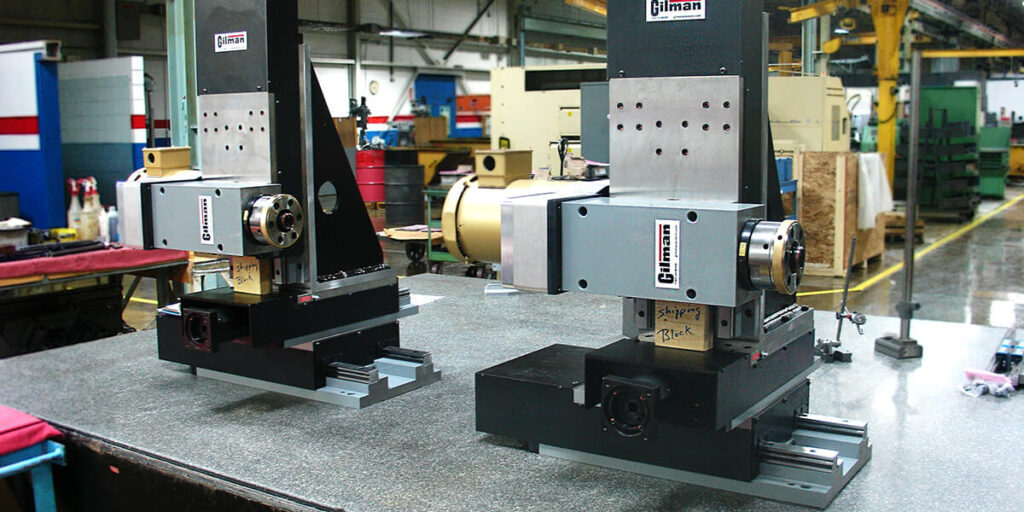

Case Study: Automation Manufacturer Addresses Unique Product Need Using Gilman Spindles

Gilman Precision has been putting its expertise in slides and spindles to use for over 70 years, working with leaders in various industries such as healthcare, paper conversion, and food manufacturing to provide them with the machine solutions they need to maximize productivity. In this case study, Gilman partnered with a nationally known robotics and…