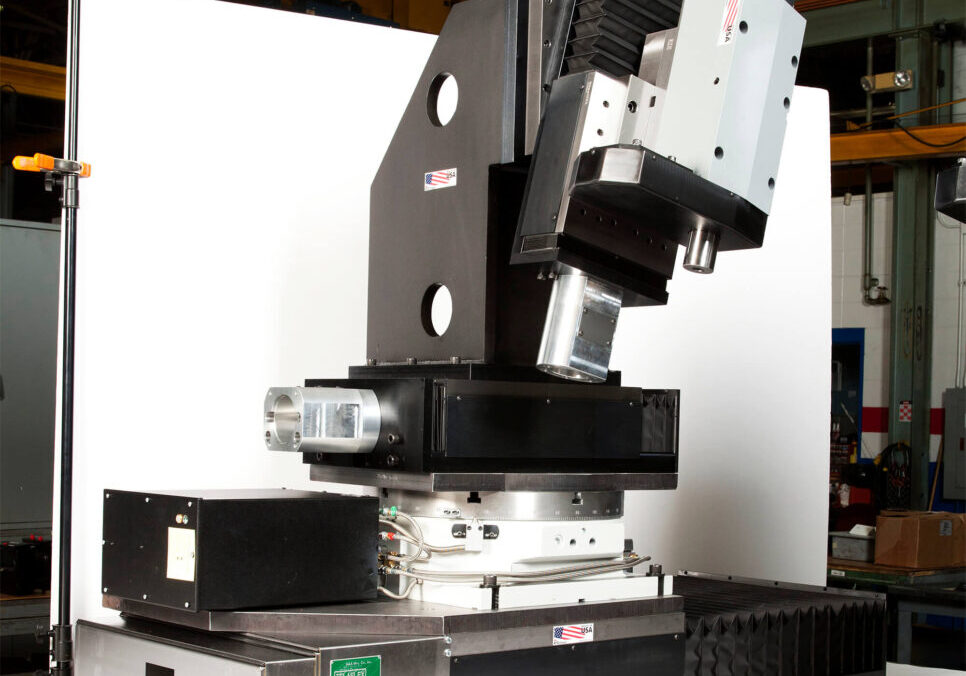

Gilman Precision’s Spindle, Slide Repair Combination a Bonus for Overall System Efficiency

Gilman Precision in Grafton, WI, offers repair service for both spindles and slides.

A properly working spindle or slide is an essential part of operations for many companies internationally, and – luckily for Binsfeld Engineering of Michigan – repair of both components is something Gilman Precision specializes in.

“There are times that we do use (our spindle) at least eight hours a day, every day, weeks on end,” said Randy Pattison, of Binsfeld Engineering. “Our initial problem was excessive vibration and noise from the spindle. We sent it in to (Gilman), and had them analyze it. They correctly analyzed the problem, gave us a quote — we offered them the opportunity to continue and repair it, which they did in a timely manner and returned it to us promptly. We were very happy with their service.”

Many spindles and slides are used in this way, operating in machinery that is running eight or more hours a day, sometimes seven days a week. This ongoing use as well as environmental factors — such as dirt, machining chips and condensation — can contribute to the failure of the spindle or slide.

“(The slides are) just worn out. A chip will get in there and it just starts wearing at something,” Gilman machinist Robin Nierode said. “Everything over time starts wearing out, and when it gets worn out then … they get lift, or — it’s just different movements that they don’t want. They’re not tight anymore.”

When taking an order to repair a spindle or slide, Gilman Precision COO Michael Weiland said it’s vital to have clear communication from the customer about the problems experienced with the slide or spindle.

“It is very important that the customer supply as much up front information as possible so that an accurate evaluation can be completed as quickly as possible,” Weiland said. “Such information includes rotational speed, failure mode, what the spindle is used for, prints, if available, and motor data, if applicable and not shown on a name plate.”

This information is helpful to Gilman as the company works to diagnose the problem with any component before moving forward with the repair.

Slides are deburred to remove the sharp edges and bearing tape before reassembly. Before shipping a slide or spindle back to any customer, Gilman will test and inspect the item — checking for things such as lift, overall height and top to bottom parallelism — to ensure everything is working properly and efficiently.

Spindles undergo an in-depth tear down with “careful inspection of all components including measurements of bearing bores, journals and spacers along with associated run-outs,” Weiland said. “An engineering analysis is then completed to make sure the physical dimensions are appropriate for the bearings and operation of the spindle.”

Processes to repair the spindle can include such steps as welding, chroming, turning and grinding, Weiland said. Spindles are eventually reassembled and balanced to match measurements taken during the inspection process.

Spindles and slides are often paired in machinery, so it can be beneficial to repair both components at once. Gilman Precision offers repair service of both parts in its shop, and the end result is a customer receiving all around system efficiency.

“Since we are manufacturer we have state of the art capabilities to do most work in house,” Weiland said. “This speeds up delivery and allows for better quality control.”

Gilman Precision has been dedicated to the advancement of high precision solutions that improve efficiency and achieve longevity since 1952. The company develops customized slides and spindles for value-added engineers with exacting needs and standards, providing expert service for virtually any manufacturer’s equipment.

If you’ve got a question on ordering or repairing a spindle or slide, contact us at 800-445-6267 or sales@gilmanprecision.com.