Case Study: Local Spindle Repair Gets Manufacturer Back Up & Running Quickly

The Customer

A global provider of services to the paper industry, with a manufacturing location in Wisconsin.

The Challenge

The customer was having downtime issues on one of their major grinding pieces of equipment, containing four spindles. Due to the heavy-duty nature of grinding and the processes involved, the spindles consistently crashed. Since the company did not have any back-up units, every time a spindle went down, that unit’s part of the production line came to a halt, resulting in a bottleneck.

Once a spindle requires repair, the customer had to send them to a partner located across the country. The repair was costly and time-consuming because of the distance. To reduce downtime and expense, the customer needed to find a local partner that could provide them with both timely and high-quality repair service, as well as a solution to help reduce manufacturing bottlenecks.

The Solution

Gilman Precision’s Spindle Repair & Engineering Process

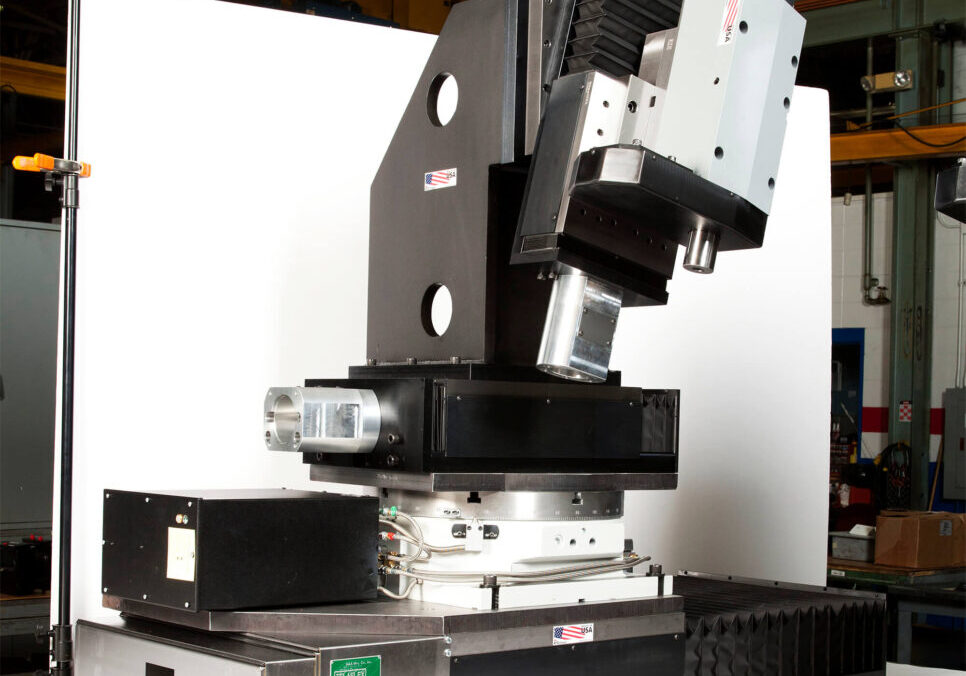

Once the customer reached out to us, we were able to drive to their work site the same day and perform a preliminary inspection to help pinpoint the issue. After this inspection was complete, we transported the spindles back to our nearby facility for a complete evaluation, which allowed us to disassemble the spindle to quickly pinpoint the issue and provide a cost to repair. During this evaluation process, we also involved our engineering team, who were able to look at the unit and design a new drop-in replacement unit for the customer.

Once the customer approved the repair, we were able to repair the spindle and thoroughly test and analyze to ensure it was working just like new.

The Outcome

Gilman Provides Back-Up Spindles

In addition to the unit we repaired, and unique to Gilman with our in-house engineering team and manufacturing facility, we were able to reverse engineering and manufacture a replacement unit as well, allowing the customer to eliminate downtime when a primary spindle fails by having a spare unit. Only a spindle manufacturer would have the knowledge and machinery to deliver a backup spindle.

These heavy-duty backup spindles last longer, leading to fewer spindle crashes and a reduction in bottlenecks.

Gilman’s Spindle Repair Process

- Machine Spindle Failure Analysis

- Spindle Component Inspection

- Price Quote

- Spindle Part Replacement & Reconditioning

- Spindle Reassembly

- Spindle Return

Gilman Precision has been providing unparalleled slide manufacturing and service for over 70 Years.