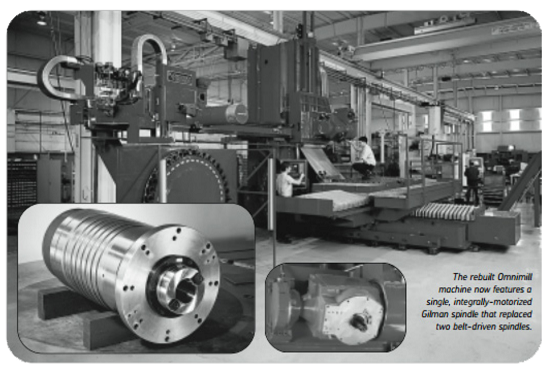

OM-3 and OM-4 Sundstrand Omnimills’ Spindle Upgrade

Single, 25 hp, CAT 50 integrally-motorized spindle replaces two belt-driven spindles.

Application

A major aircraft engine manufacturer wanted to upgrade to the spindle on its OM-3 and OM-4 Sundstand Omnimills (5-axis machining centers with a 150 degree tilting head). Material being machined was inconel, titanuim and other aerospace alloys.

Challenge

Converting the original two-spindle arrangement (a lowspeed spindle to handle large tools and a high-speed spindle for small tools) presented a number of challenges. A conventional rebuild would require a completely new slide casting together with a twospeed, timing, belt-coupled spindle cartridge requiring oil-bath bearing lubrication, a complicated design that would be both hard to adjust and maintain.

Solutions

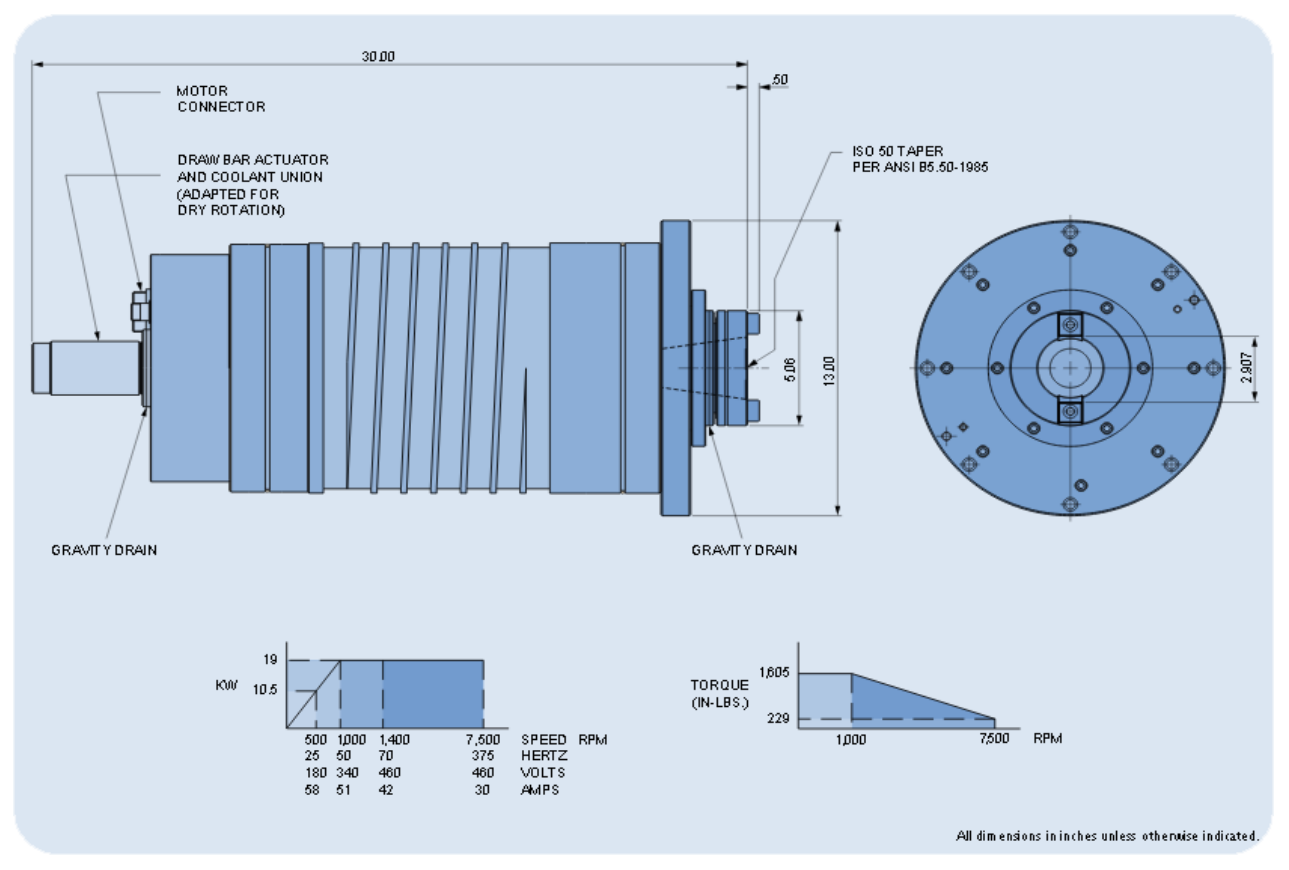

Instead of redesigning the head to accommodate a conventional belt-driven spindle, the machine builder suggested an integrally-motorized spindle for better functionality. Ultimately, the solution came in the form of a single 25 hp (18.6 kW) spindle, capable of 7,500 RPM, with CAT 50 taper and through-spindle coolant. A stock spindle being unavailable, a Gilman engineering team visited the rebuilder to review the application. After research, the engineers recommened Indramat windings to fit within the severe space constraints of the head. A new head casting configuration, machined to allow coolant to circulate around the spindle body, allowed the spindle to drop into the housing and bolt through a flange, making spindle removal an under-30-minute job. To eliminate the problem of a hose band moving with the tilt head, the housing is also innerdrilled and plumbed to handle all hydraulic, coolant, and electrical requirements.

Technical Specifications

Spindle:

- Preloaded Triplex set ABEC 7, 25° hybrid ceramic angular contact ball bearings nose end (90mm I.D.)

- Preloaded pair ABEC 7, 15° angular contact ball bearings back end (70mm I.D.)

- Kluber NBU15 grease lubrication

- Inpro VBX seals each end

- Indramat encoder feed back for closed loop operation with Indramat drive

- OTT Hydraulic draw bar with coolant thru and taper air blast cleaning

- 7,500 RPM maximum

- Maximum thrust into spindle 1,200 lbs.

Motor:

- The spindle is driven by an Indramat intelligent AC vector drive. Stop and orient mode takes less than 3 seconds at 7,500 RPM. The rebuilt machine has a wide range of speeds without gear changes.

Cost Savings

Redesigning and rebuilding the user approximately one half the cost of a new machine. Six machines have been converted to date.

Time Line

Total project time, from initial consultation to spindle delivery, was 18 weeks.

Request A Quote

To request a quote, please contact us using the contact form.

Use our product configurator to download a drawing to use in your design.

If you you would like to reach us directly, give us a call at 262-377-2434.