When Timelines Are Tight, Trust Gilman Spindles

Precision-engineered CNC spindle systems delivered fast — with CAD support and expert guidance.

Gilman is the first call for OEM engineers who can’t afford risk. From design to delivery, we make sure your spindle performs right the first time.

IS09001:2015 Certified | 70+ Years Experience | CAD & Engineering Support

Get Expert Input on Your Next Spindle Project

Have a challenging application or tight timeline? Let’s talk it through. Our engineers will review your requirements and provide feedback — fast.

Why engineers contact Gilman:

- Rapid response — most quote requests answered in 1 business day

- Direct engineering support, not a sales rep

- CAD files, integration guidance, and manufacturing timelines included

"*" indicates required fields

Gilman Precision Spindles Are Trusted By

Our custom CNC spindle solutions are built for high-performance environments —

designed specifically to your tolerance, size, and speed requirements.

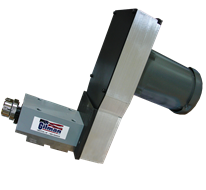

Custom Spindle Capabilities

- CNC Milling Spindles

- CNC Spindle Motors (AC/DC)

- Belt-Driven or Integral Motor Spindles

- Cartridge & Block-Style Spindles

- High-Speed Grinding Spindles

- Slide & Spindle Integration

- Spindle Repair & Rebuild Services

- Power: up to 100 HP

- Speed: up to 24,000 RPM

- Mounting: Foot, Flange, Cartridge

- Bearing Types: Angular Contact, Hybrid Ceramic, Roller

- Cooling: Air or Liquid

- Available Configurations: Single or Multi-Spindle Modules

CAD models available

Application-specific engineering

In-house design, build, and test

Why Engineers Start With Gilman

Confidence From Day One

Our spindles are engineered to perform right the first time — no tuning, no field fixes, no surprises. You can spec Gilman with confidence and keep your project on track.

Custom, Not Compromised

Every spindle is purpose-built to your exact application. No off-the-shelf limitations. No unnecessary rework. Just the right fit, right away.

Direct Access to Experts

When you work with Gilman, you're not handed off to sales. You're talking directly with engineers who understand your design constraints and performance goals.

CAD and Specs Upfront

Download CAD files and spec sheets right from our configurator, or get quick access through our engineering team — helping you finalize design and integration faster.

Machine-Level Understanding

We don’t just make spindles — we understand how they fit into full machine systems. That means better integration, better support, and better long-term performance.

Unmatched Proven Experience

With over 70 years of engineering excellence behind every design, Gilman has the track record to back every claim. We’ve solved the tough problems before — and we’ll do it again.

Responsive, Reliable Lead Times

Tired of vendors ghosting you? We’re not that kind of partner. We provide clear timelines, honest updates, and fast answers — because your schedule matters.

Certified Quality You Can Stand Behind

IS09001-certified, U.S.-built, and performance tested in-house. You’ll never have to wonder whether a Gilman spindle meets spec — it already does.

Case Study: Belt‑Driven Three‑Spindle Cluster Module

An outdoor power equipment OEM needed a high‑precision machining solution for their engine casting production line. The design challenge: integrate three belt‑driven spindles into a compact, dial‑type machine station with extremely tight center‑line tolerances and uninterruptible tooling operation.

Solution by Gilman Precision:

- Designed a three‑spindle cluster using 4000C‑series belt‑driven spindles

- Two spindles at 4,620 RPM, one at 2,310 RPM, driven from the rear

- Equipped with 55 mm nose bearings, 45 mm drive bearings, ABEC‑7 angular‑contact, synthetic grease, labyrinth seals, and air‑purge provisions front and rear

- Mounted on hardened‑way Gilman slide assemblies with hydraulic cylinder actuation

- Initial spec for pitch location was .0005", but Gilman’s modules achieved exceptional accuracy within .0002"

Results:

- Met extreme bore‑location requirements without the customer’s anticipated “steering” needed

- Enabled simultaneous machining of three critical areas on engine castings in one station

- Delivered compact and benchmark performance in a tightly packed production environment

Explore Our Product Configurator

Download 3D models, review specs, and explore spindle configurations instantly — without waiting for a rep.

Access dimensional drawings, 3D files, and performance data across our full spindle lineup:

- Belt-Driven Spindles

- Integral Motorized Spindles

- Cartridge, Flange & Block Mounts

- Slide + Spindle Assemblies

Available File Formats:

- STEP (.stp)

- SolidWorks (.sldprt)

- IGES (.igs)

- Parasolid (.x_t)

- 2D PDFs (.pdf)

- DXF (.dxf)

Fast-track your spindle selection process and minimize engineering delays.

Need help determining the right spindle?

Start a conversation with our engineering team or download drawings directly to accelerate your build.

Request A Quote

To request a quote, please contact us using the contact form.

Use our product configurator to download a drawing to use in your design.

If you you would like to reach us directly, give us a call at 262-377-2434.