Slide Repairs – When and Why it is Important

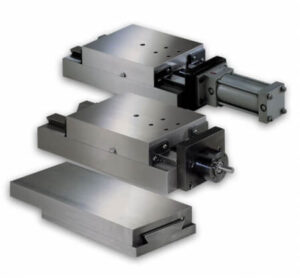

It does not matter what type of slide you have; at some point it is going to need to be repaired. You will find different slides can take more wear and tear than others and last longer. For example, dovetail slides and hardened box way slides are similar types of slides but the hardened box slide will typically last longer.

Slides are often found in machinery that is running eight or more hours a day, sometimes seven days a week. This ongoing use as well as environmental factors — such as dirt, machining chips, and coolants — can contribute to the failure of the slide, and therefore an inability to create quality components. So, it is important to know when to repair your slides.

How long do slides typically last before needing repair?

This depends on a number of factors, but the main factors are the environment you are using the slide in and the use of the proper amount of lubrication. The environment will determine the number of contaminants that encounter the surface of the slide, the more contaminants will typically shorten the lifespan.

The best way to combat the contaminants is with proper lubrication because this will help expel the contaminants and keep them away from the surface, thus, extending the life of the slide.

Accuracy is important in the manufacturing industry, and properly functioning machinery is an essential building block to meeting many industry standards. The more accuracy you need the shorter your life expectancy will be. This is dependent on your requirement of the slide, but if you do not need precise accuracy, your slide can tolerate more wear.

What are some signs your slides need to be repaired?

The two most common signs that your slide needs repair are:

- Loss of holding tolerance

- Visual wear and tear on your slide

Why is it important to repair my slides on time?

The main reason can be summarized in one word, downtime. If you plan ahead you can schedule your slide repairs which will lead to a shorter downtime. If you wait until the slide absolutely needs to be repaired, downtime will increase and generally be unexpected. This then can cause production shutdowns and delays.

Additionally, if you wait too long to get your slide repaired, the slide might be beyond repair or it might be more cost effective to purchase a new slide. This is due to extreme wear on the slide that can’t be reconditioned. Slides are designed to move with accuracy and when they wear out, it can no longer hold tolerance. Scheduling routine service on your slide will save you time, money, and production delays.

Why Gilman Precision?

It doesn’t matter if you need a linear guide slide, a hardened box way slide or a dovetail slide repaired, Gilman Precision will get the job done. Our years of experience allows us to repair almost any slide on the market despite who manufactured it.

Gilman Precision is an industry leader for manufacturing precision slides. This provides us a number of advantages when it comes to slide service. We have the expertise and the equipment all under one roof so there is no third-party involvement.

Our experience allows us to know what is required which leads to higher quality repairs that come out like new. Having everything under one roof enables us to provide shorter lead times which means shorter downtimes for you.

Gilman Precision has been providing unparalleled slide manufacturing and service for over 70 Years.