Idea Bulletin

Custom Drilling Module Gilman designed crankshaft drilling module changes customer's process paradigm

Application

A tier one automotive supplier of engine crankshafts needed to improve the oil hole drilling operation of their transfer line style process. This high volume machining operation required accuracy, reliability and repeatability in a compact work envelope.

Challenge

The depth of the hole being drilled and the irregular shape of the crankshaft required the drills themselves to be quite long, extending approximately 12 inches from the tool-holder. The customer required runout accuracy of the drills to be within .0003 inches (TIR) at the spindle gage line and within .001 inch (TIR) 12 inches out from the gage line. Even with the help of a bushing plate, this was a significant challenge.

Solution

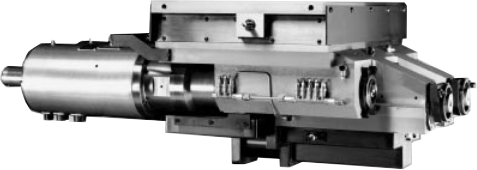

Starting with the customer’s desired work envelope, Gilman engineers designed a special module incorporating integral motor spindles to drive the drills and Gilman’s Quad-Quill precision feed unit to reach, grasp and position the drill bushing plate. Positioning the bushing plate was a key issue as each crankshaft was drilled twice at the station, with an off-line tool-change between the first and second drilling cycle.

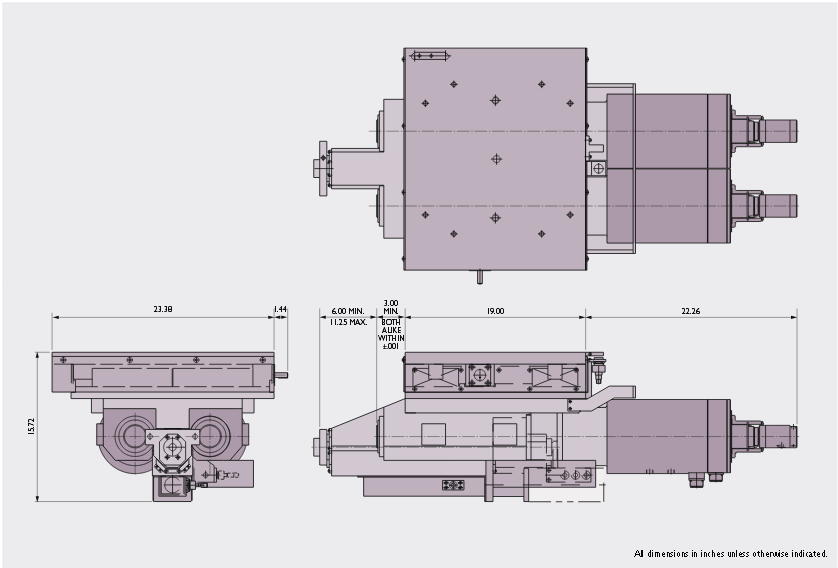

To accommodate different part requirements, two modules were designed. One unit used two spindles and one Quad- Quill. A second unit was designed with three drilling spindles and two Quad-Quill units. The spindles and Quad- Quill units were precision- mounted (centerlines located to within .001 inch) in a casting. The casting interfaces with the customer’s machine structure via a GLRW style roller bearing slide that is driven by a metric ground ball screw.

The spindles are custom designed units rated at 2.2 kW continuous power from 1.500 to 4,000 RPM. They feature HSK 63A tooling tapers with air purge, automatic draw-bars and high-pressure coolant through the spindle and drill. The spindle motor housing is liquid cooled for heat dissipation and contamination protection.

The Quad-Quill feed units are also custom designs. While still an eight-sided form, the quill’s height is greater than its width. This maintains the rigid location of the quill while minimizing the width of the overall assembly. The customer supplied and mounted a Fanuc servo motor to drive the Quad- Quill feed mechanism.

The success of the design at putting accuracy, rigidity and reliability in a small work envelope prompted one of the customer’s engineers to remark that it “destroyed the existing paradigm of how this job should be done”.

Technical Specifications

Slide:

• SPGLRW19-2I.28-23.38-D2-2

• Special GLRW type slide

• Metric, Ground Ball Screw

• Electric Motor Drive

Spindle Selection:

• 081-X4M-H63A--2.2/1500LC

• Bearings - Nose: 65mm I.D., triplex set, ABEC 7, 15°, angular contact

• Bearings - Rear: 85mm I.D., pair, ABEC 7, 15°, angular contact

• Grease lubricated bearings

• Speed Range: 1,500 - 4,000 RPM

Quad-Quill:

• Gilman Custom Design

Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect, or consequential arising out of use of the information contained herein.

Request A Quote

To request a quote, please contact us using the contact form.

Use our product configurator to download a drawing to use in your design.

If you you would like to reach us directly, give us a call at 262-377-2434.