How Gilman Precision Built a Tire Balancing Spindle for the Automotive Industry

A machine integrator within the automotive industry approached Gilman Precision with a unique challenge; they needed to develop a spindle assembly for balancing tires that also required a way to deliver compressed air through the shaft without a typical rotary union. The Gilman team leveraged their expertise in spindle technology to create a solution that not only met specific criteria but exceeded expectations while ensuring reliable performance.

Building a Better Spindle: A Collaborative Effort

The engineering team at Gilman Precision and the machine integrator collaborated to analyze the unique requirements. These detailed discussions were essential to gaining a comprehensive understanding of past challenges and current needs. The Gilman team harnessed this knowledge and applied their own design principles focusing on providing a reliable solution with an exceptional outcome.

Delivering High Quality, Custom-Engineered Solutions

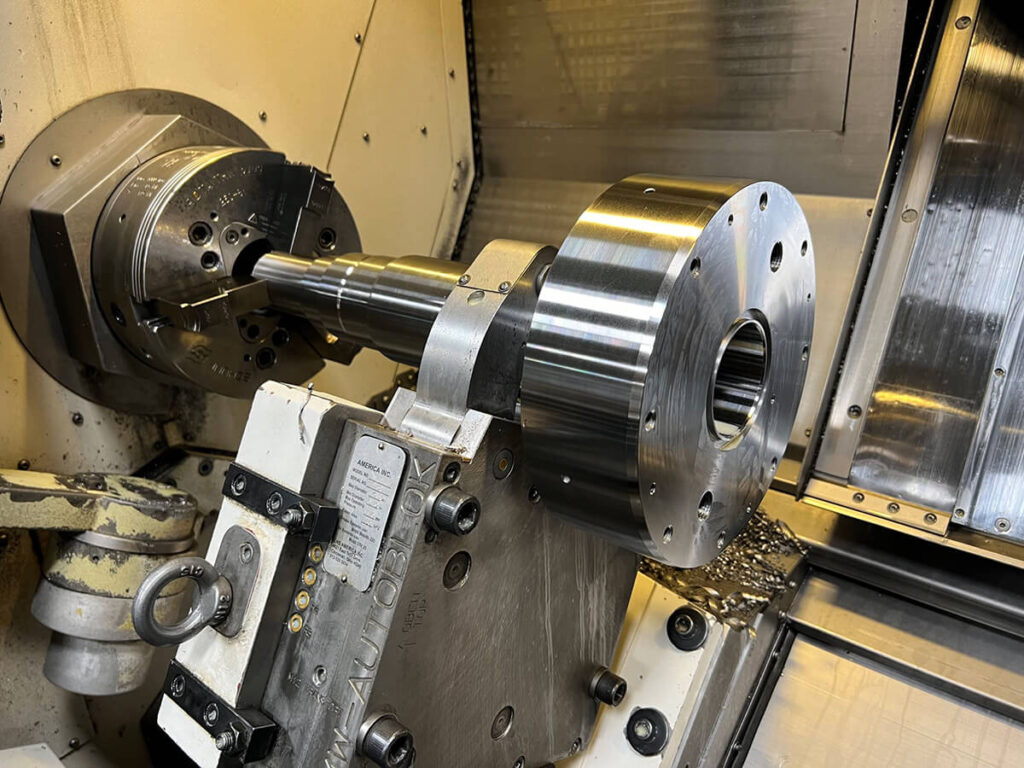

The Gilman team went to work, implementing a design to optimize performance. The spindle bearings were upgraded to high precision, angular contact, ABEC 7 units. To deliver compressed air to inflate a mounted tire, provisions were added to the assembly including special carbon fiber reinforced lip seals inside the spindle housing and shaft. These seals satisfied the requirement of providing pressurized air to the tire while preventing blow-by into the spindle bearings. The specification of 1 psi per minute loss at 60 psi was easily attained through time-tested engineering and manufacturing techniques. This approach allowed the customer to directly mount the drive motor, leading to a streamlined, cost-effective design.

This successful project, marked by open communication and a focus on the customers’ needs, exemplifies Gilman’s continued dedication to high-quality, custom-engineered solutions that exceed expectations.

Partner with a Gilman Engineer for Your Next Project