Case Study: Automation Manufacturer Addresses Unique Product Need Using Gilman Spindles

Gilman Precision has been putting its expertise in slides and spindles to use for over 70 years, working with leaders in various industries such as healthcare, paper conversion, and food manufacturing to provide them with the machine solutions they need to maximize productivity.

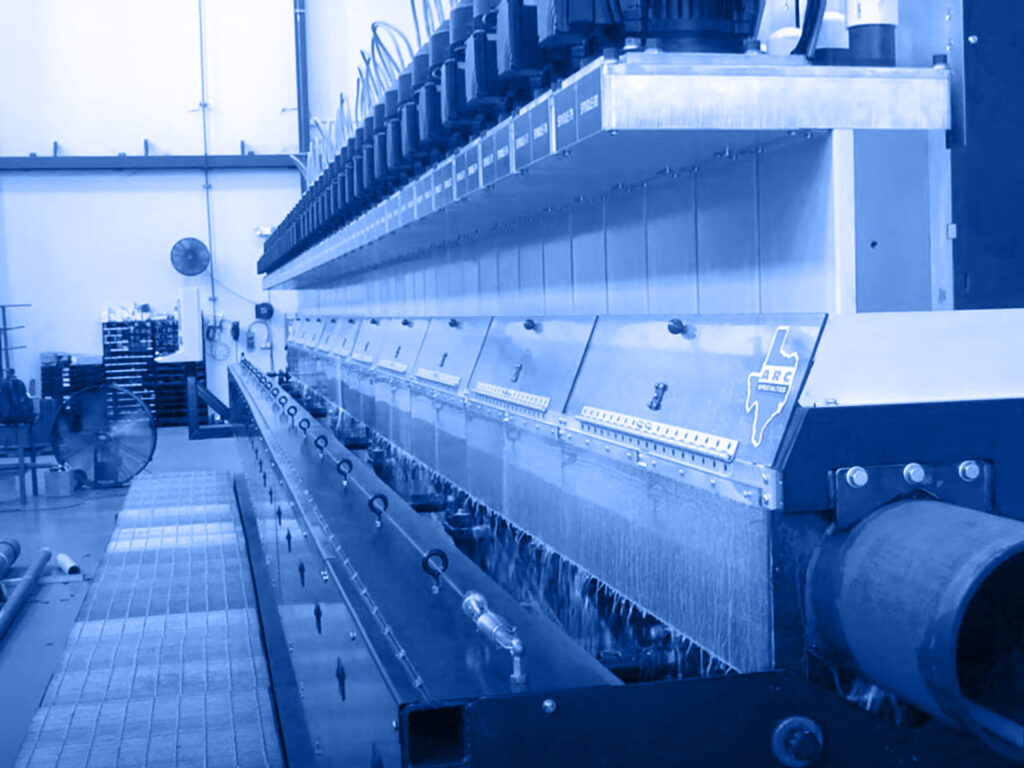

In this case study, Gilman partnered with a nationally known robotics and automation company to help identify and address a unique manufacturing need that used 80 Gilman spindles to drill holes into pipes that underlay the sand control screens used for underground drilling.

Multi-Spindle Hole Drilling System

Sand control screens are used during oil and gas drilling to filter rocks, sand, and sediment. This system requires large 40’ long pipes perforated with up to 6,000 small holes to go under the screens. While it may sound like a time-consuming process, this manufacturer is now able to drill thousands of holes in a matter of minutes with the help of a machine equipped with 80 Gilman spindles.

This machine utilizes 4000 size Gilman spindles, which feature a #40 taper tool connection, direct drive servo motor housing, robust bearing and seal design, and a special motor coupling to make tool changing fast and easy.

The high quality and dependability of Gilman’s spindles allow the manufacturer to increase their machine’s productivity.

Need to find the right slide or spindle for your machine?

Gilman Precision’s easy-to-use Product Configurator allows you to download CAD files and view 3D models of your slide or spindle for free, ensuring you’re getting exactly what your machine needs.

If you have a slide or spindle in need of repair, contact a Gilman technician at 262-377-2434 or sales@gilmanprecision.com.