Custom CNC Spindle Repair Services

Get Your Spindle Back Online—Fast, Reliable Repairs

Unplanned spindle failures can halt production at thousands per hour. Gilman Precision’s expert repair services restore your spindles to OEM or better specifications—minimizing downtime and maximizing life.

ISO 9001:2015 Certified • 70+ Years of Service Expertise • Transparent Timelines

Request Your Repair Quote

- Rapid Production Recovery: Clear repair plan & timeline in 24 hrs

- No‑Guesswork Diagnosis: Root‑cause analysis prevents repeat failures

- Single‑Source Expertise: Multi‑brand spindle capability backed by 70+ yrs experience

Our Spindle Repair Capabilities

Comprehensive Inspection & Root‑Cause Diagnosis

Thorough teardown and performance testing to pinpoint issues—no band‑aids.

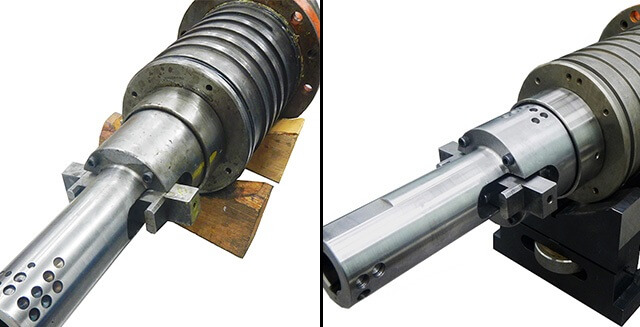

Precision Restoration to OEM Specs

Rotor regrind, stator rewind, bearing replacement, and dynamic balancing.

Seal, Bearing & Cooling System Overhaul

Labyrinth or lip seal replacement, synthetic grease refilling, liquid‑cool upgrades.

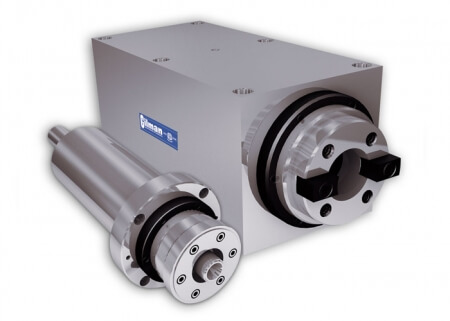

High‑Speed & High‑Torque Spindle Rebuilds

Cartridge, block, and motorized spindle services to match original performance.

Dynamic Testing & Quality Validation

Vibration analysis, run‑out measurement, and full-speed no‑load testing prior to shipment.

Retrofit & Performance Upgrades

Extend service life and boost performance with precision retrofits:

- Upgraded Bearing Systems for higher RPM and load capacity

- Enhanced Cooling Packages (air, liquid) to maintain thermal stability

- Bearingless Spindle Conversions for reduced maintenance

- Custom Shaft Modifications to fit new tooling or adapt to retrofits

All work performed under our ISO 9001:2015 quality system, ensuring traceability and consistent results.

Why Operations Have Trusted Gilman for Over 70 Years:

1. Minimized Downtime with Proven Reliability

Repairs engineered for maximum uptime—so you meet production targets.

2. Thorough & Accurate Diagnosis

Root‑cause assessment prevents repeat failures and costly surprises.

3. Precision Restoration to Original Specs

Spindles rebuilt to perform like new—or better—from day one.

4. Extensive Multi‑Brand Expertise

One partner for all spindle brands and types—no juggling multiple vendors.

5. Transparent Communication & Honest Timelines

Know exactly when your spindle will return to service.

6. Optimized Performance for Longer Life

Repairs and upgrades that extend service intervals and reduce total cost of ownership.

7. Post‑Repair Support & Assurance

Installation guidance, inspection reports, and a 30‑day completion check‑in.

“Every hour offline costs us $10 k+. Gilman’s speed and quality keep our lines up.”

– Director of Operations, Heavy‑Equipment Manufacturer

Get Started On Your No-Obligation Repair Quote

How It Works

1. Submit Your Repair Request

Use the form above or call us—emergency service available.

2. Comprehensive Inspection & Quote

Tear‑down, root‑cause analysis, and clear cost/time estimate.

3. Precision Repair & Testing

Rotor regrind, bearing swaps, dynamic balancing, and performance validation.

4. Return to Service & Follow‑Up

Fast shipping, installation support, and a 30‑day project completion check‑in.

Ready to Minimize Downtime?

Request A Quote

To request a quote, please contact us using the contact form.

Use our product configurator to download a drawing to use in your design.

If you you would like to reach us directly, give us a call at 262-377-2434.