8 Key Spindle Basics to Optimize Your Machine’s Productivity

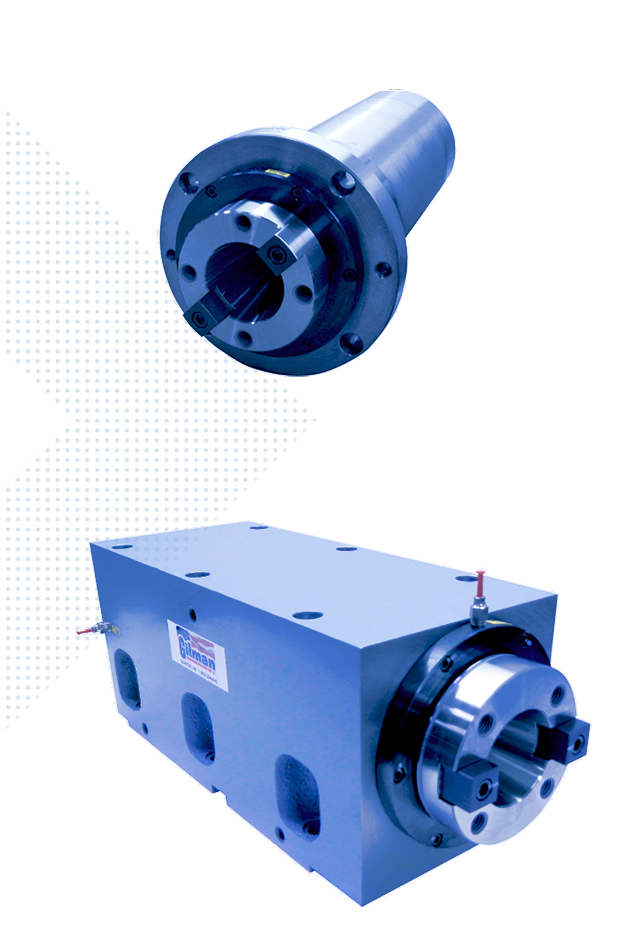

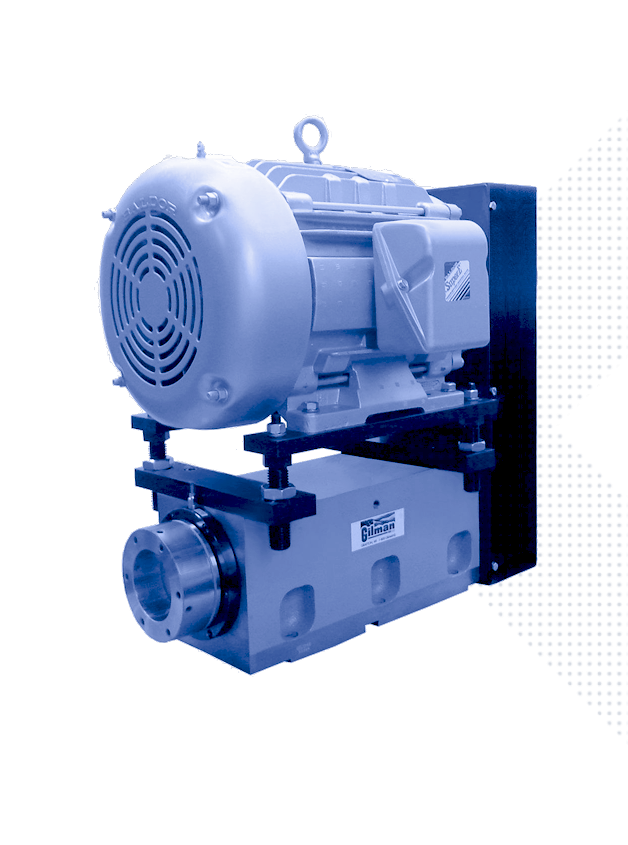

Different spindles and components are used for different machines, and choosing the wrong spindle type can impact your machine’s efficiency and effectiveness. As trusted spindle experts for over 70 years, we know the key components and specifications required to fit your custom machining solution. Below are some spindle basics you should consider to help optimize your machine’s performance.

Understanding Precision Spindles

1. Steel Bearings – The common choice for precision spindles, steel bearings are preloaded by adjusting them axially against each other or preloading them with springs. Angular contact bearings support both radial and axial loads and have different contact angles, the most common of which are 15 and 25 degrees. The higher the contact angle, the more axial load capacity.

2. Ceramic Bearings – Ceramic bearings, or hybrid angular contact bearings, are used to either increase speed or lower operating temperature. These bearings use steel inner and outer rings with ceramic balls, and the basic principles of hybrid ceramic angular contact bearings are the same as the steel type.

3. Angular Contact Bearings – Angular contact bearings use asymmetric axial races and are used to support loading in both the axial and radial directions. For higher axial loads, use triplex bearing constructions.

4. ABEC Rating – ABEC is the scaled description of bearing tolerances developed by the Annular Bearing Engineering Committee. There are five grades: 1, 3, 5, 7, and 9. The higher the number, the greater the precision of the bearing. There are also ISO standards for bearing precision, ISO 492. ISO has five grades – 6X, 6, 5, 4, and 2 – where the lower the number means the higher the precision.

5. Lubrication – Spindle bearings are lubricated by two forms, either fluid lubricants (oils) or thickened fluid lubricants (greases). Fluid lubricants are applied by oil mist, oil and air, or oil jet. Greases are packed in the bearings using specific amounts, and there are many types of greases available depending on the speed required, load, and environment. Gilman uses high-performance synthetic greases in their spindles as standard, while fluid lubrication is available as a special design.

6. Labyrinth Seals – These non-contact seals have passages designed to make it difficult for contaminants to reach from the outside of the spindle to the bearings. Labyrinth seals are used in applications where high speeds prevent the use of contact seals, and are assisted in effectiveness by the use of air flowing out of the seal to the outside or what is called air purge.

7. Contact Seals – Contact seals are the preferred sealing method for keeping contaminants from reaching the spindle bearings. Because of the friction produced, they’re limited as far as speed. They may also be assisted by using air purge.

8. Balancing – If a rotor is unbalanced while rotating, it’ll revolve around its mass center axis, causing it to vibrate and inflict damage to the bearings. This vibration also creates unnecessary noise. Therefore, it’s necessary to reduce the unbalance to an acceptable limit or balancing grade, typically ISO G1.0 or G0.4.

Looking For More Information?

For Gilman Precision’s complete spindle selection and more information regarding size, type, speed, and other spindle solutions, download our spindle catalog. Not sure what type of spindle specifications you need? Speak with one of our spindle experts by calling 262-377-2434. If you need to request a quote for repairing an existing spindle, turn directly to the experts at Gilman Precision for all your spindle manufacturing needs.