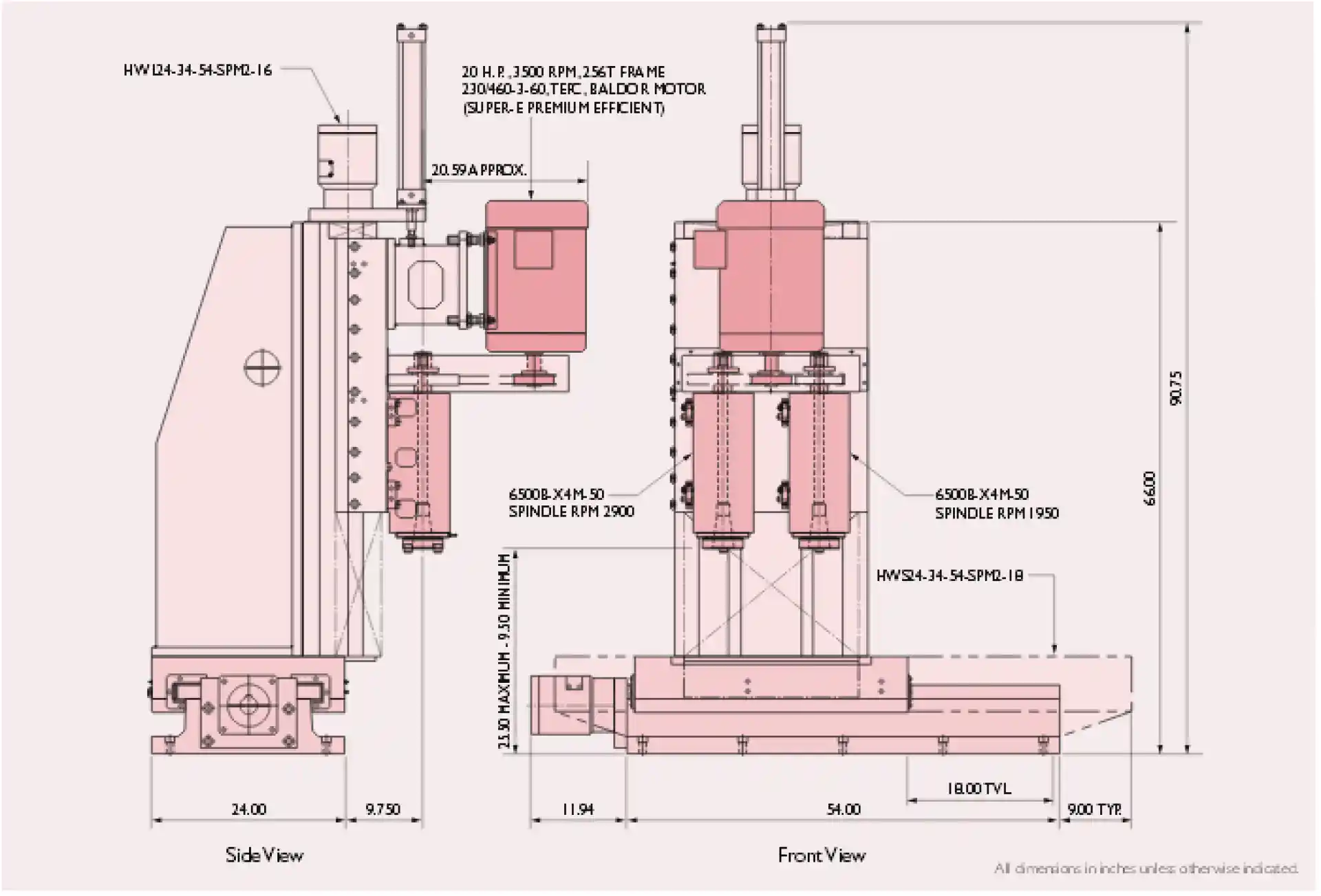

An American motorcycle manufacturer was gearing up for increased production of their large touring motorcycles. Operations required on this dual spindle multi-axis boring machine were center drill and spot face for the first spindle and 1-1/2” boring operations for the second spindle. The material being worked was Timken cast iron.

Because the existing 10-year old dual spindle drilling and boring machine could not keep up with the required production rates, the manufacturer decided to replace it. Among the highest priorities for the replacement machine was a design with more vertical rigidity to allow for faster feed rates and thus shorter cycle times.

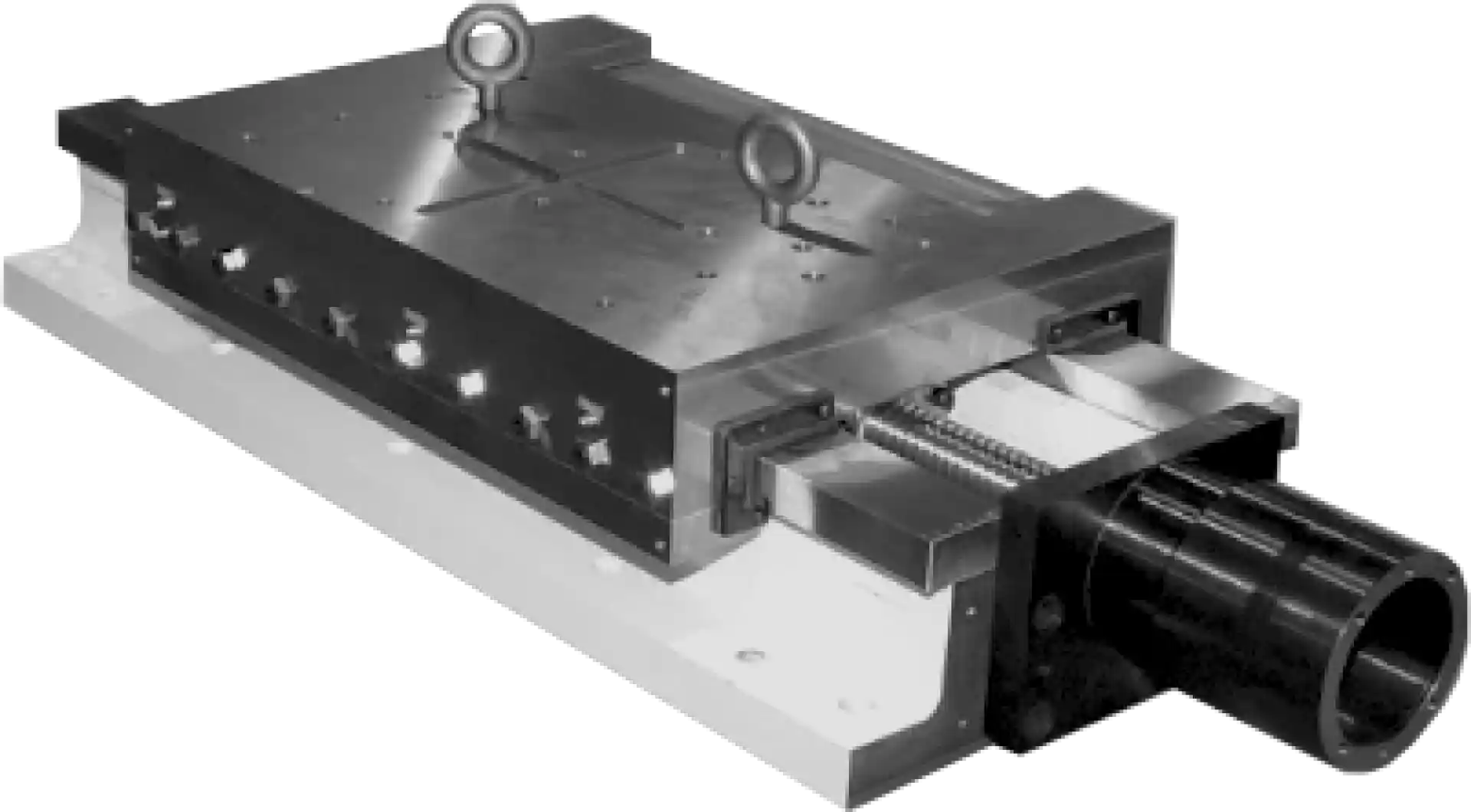

Through a joint development process including the manufacturer, the machine tool builder and Gilman, a unit was designed that met all of the end-user requirements. The base chosen was a hardened steel way slide with preloaded ground ball screw driven by a single phase motor. A vertical angle bracket supports another hardened steel way slide with preloaded ground ball screw driven by a single-phase motor. Spindles chosen were Gilman model 6500B with a block housing and triplex ball nose bearing arrangement and labyrinth seal. The shaft nose was 50 NMTB taper. The design retained the single motor drive. The customer supplied reduction unit turns the first spindle at 2,900 RPM and the second spindle at 1,950 RPM.

Factoring in increased production, the machine investment is predicted to begin returning dividends in 18 months. The robust design has a safety factor of 1.5 of current capacity and allows for future improvements in tooling and new materials.

Total time from initial concepts to cutting was 14 weeks.