A transfer line processing automotive engine pistons required a compact finishing station for the wrist-pin bore. While the machining done at the station would be light, the location accuracy, inside diameter dimensions and surface finish quality had to be ”dead on” when the parts left the station.

The spindles at each of the four processing positions had to be highly accurate and vibration free to achieve the end user’s surface finish needs. They also had to be mounted close together and maintain a center-to-center dimension of .001”. Since the four spindles would have to move up to the work and then back away from it after the operation was complete, a precision slide would be required. Overall reliability of the station had to meet the “24-7-365” production needs of today’s automotive manufacturing environment.

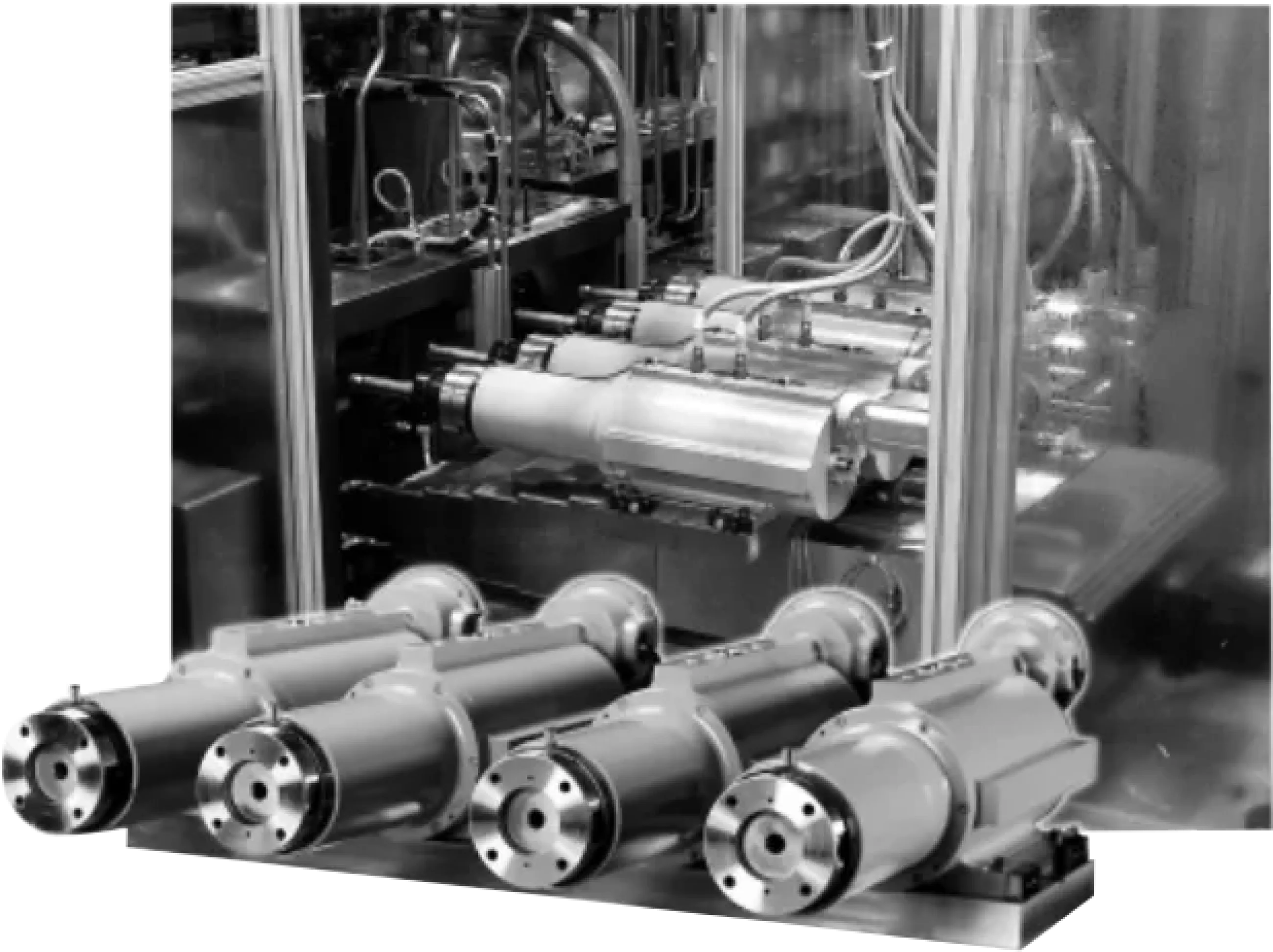

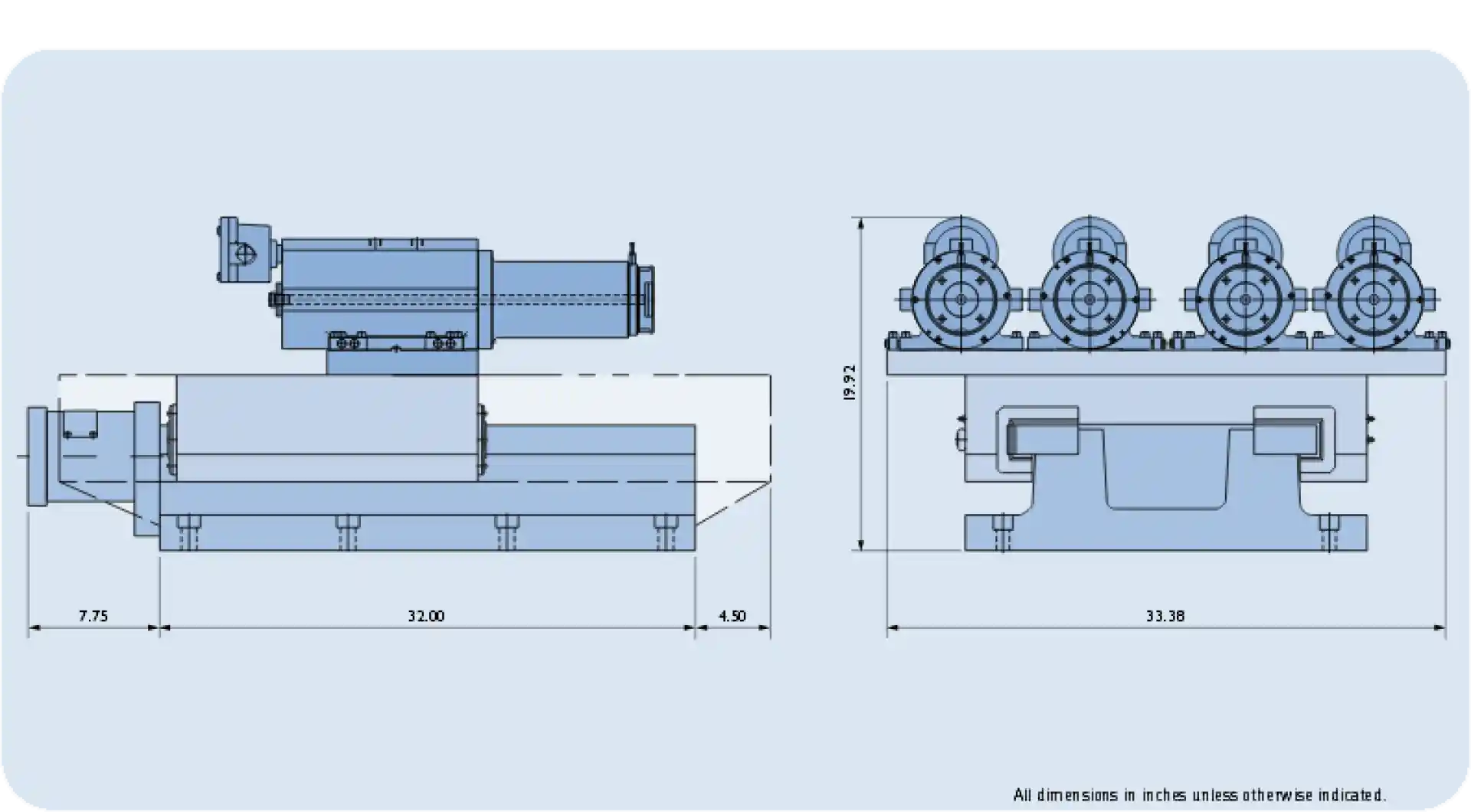

Four Gilman GLS120 motorized spindles mounted on a HWL24 “low profile” hardened way slide were chosen as the solution. The spindles featured flanged-foot housings secured to a precision mounting plate atop the ground ball screw- driven slide. The GLS120 spindles were extremely low in vibration. Their integral motor design minimized the number of moving parts and the spindle shaft and rotor were precision balanced before assembly. Precision ABEC 7/9 bearings, a triplex set in the spindle nose and a duplex in the rear, delivered rotational accuracy with a maximum runout of .0001”. Liquid cooling of the spindle housing provided a clean and stable environment for the bearings and motor. The integral motor design of the spindles also contributed to a very compact station. Individual integral motors also helped achieve a control goal for the builder. The ability of the line to process fewer than the four parts per station was felt to be a key feature that would keep the line running in the event that any of the processing positions at any of the line’s stations went down. The rough cut boring station that preceded this finishing station also featured Gilman Precision spindles and components.