A manufacturer of products for the truck industry needed to increase their drilling capacity and flexibility and add CNC capabilities to their manufacturing line.

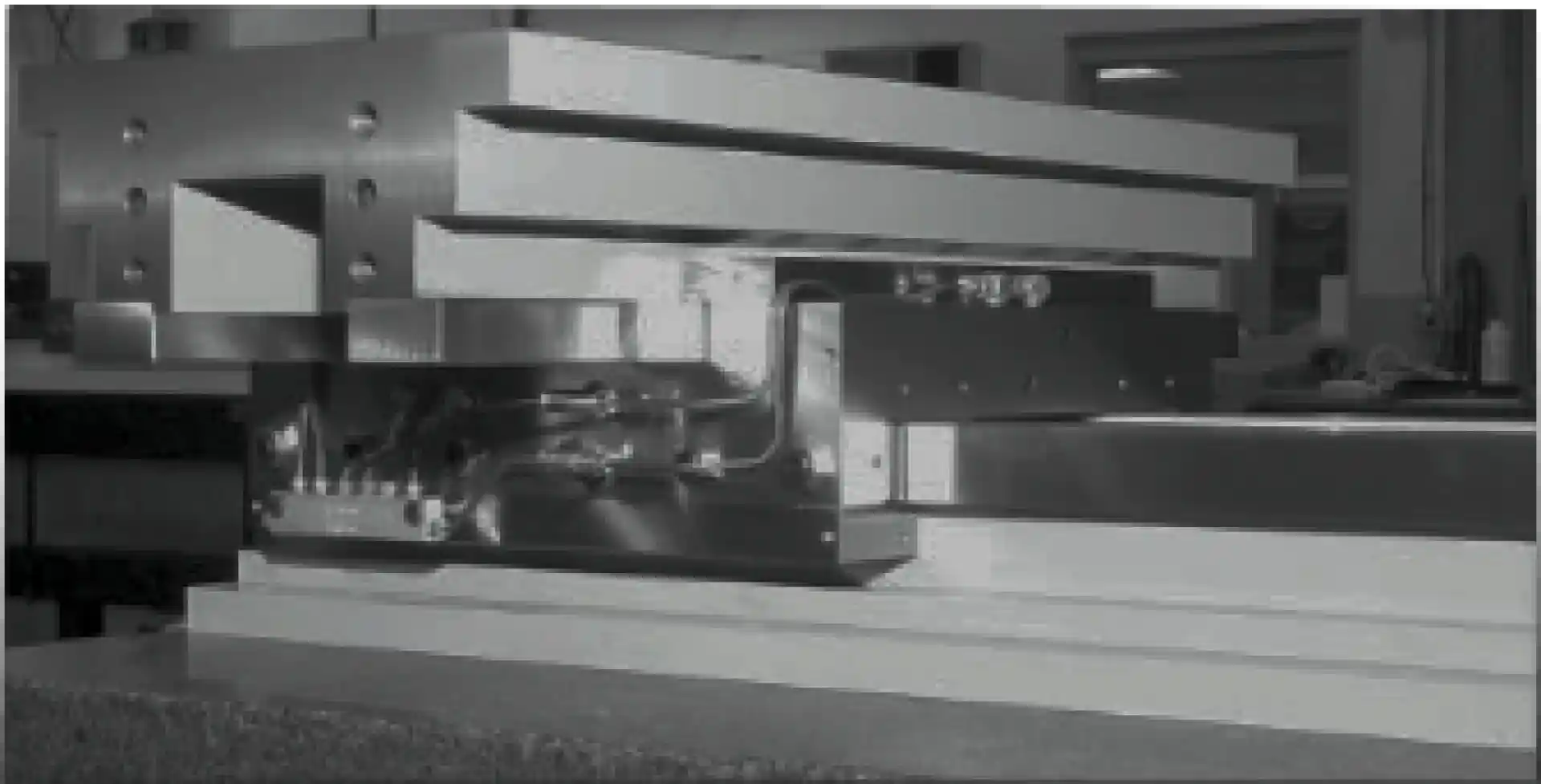

The objective was twofold: Increase drilling speeds and eliminate dedicated drilling machines. Their challenge was compounded by the fact that multiple product production required labor-intensive manual adjustments and/or dedicated machines for each product model. The ideal solution would significantly decrease changeover times while reducing floor space requirements and maintaining a low profile. The low profile was necessary to have the unit integrate with existing equipment.

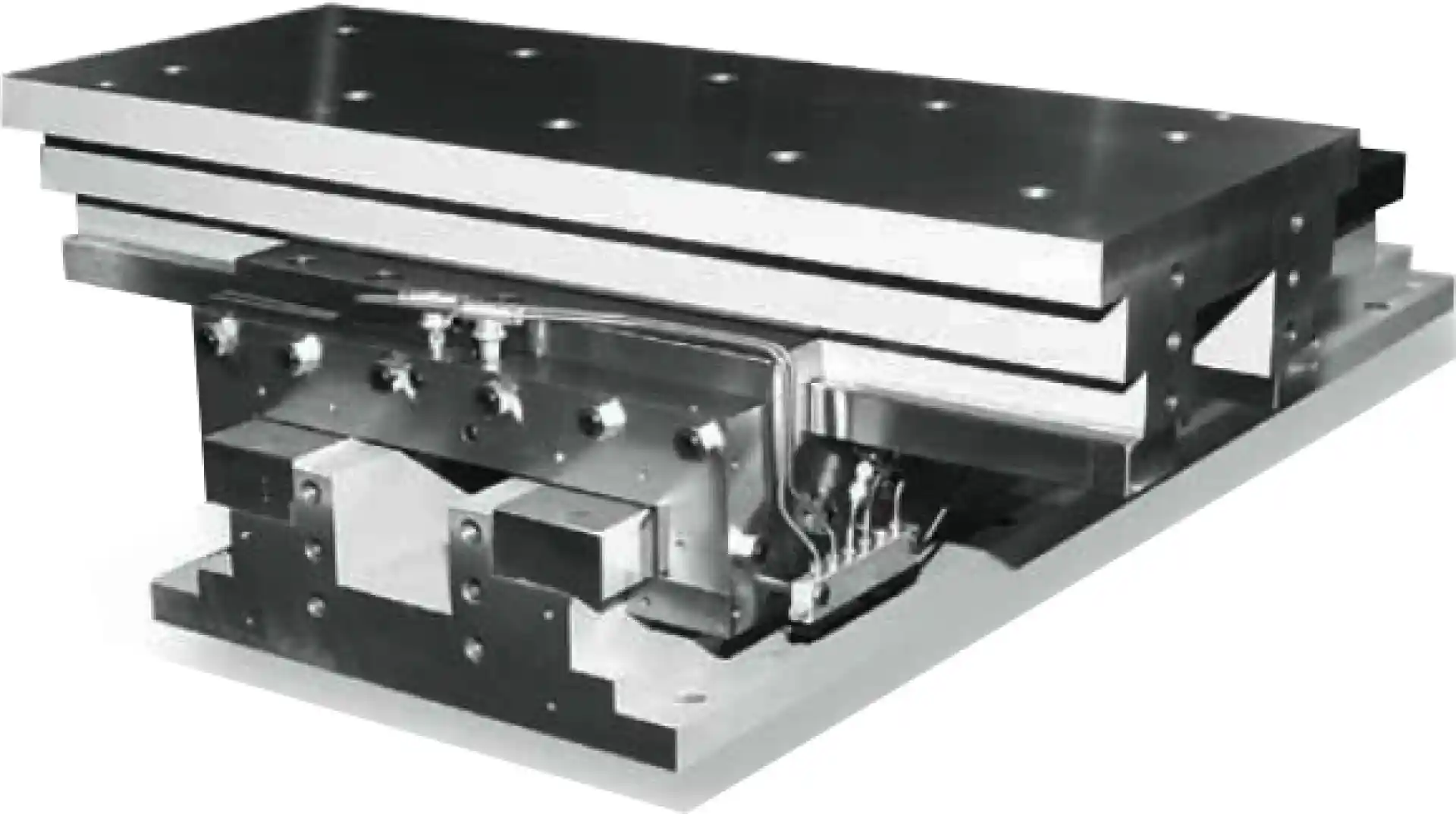

The project was let to several custom machines builders but all declined to bid; the speeds and cycle times requested were beyond their design experiences. Having decided to design and build the unit themselves, the company called on Gilman for assistance. After consultation with Gilman , they selected hardened way slides to achieve the duty cycle required. “Build it strong and you can’t go wrong,” was the company’s design philosophy, and Gilman components were up to the challenge. The final design replaced several machines and setup times were reduced from hours to minutes.

The first unit was so successful that seven more have since been constructed, achieving the company’s goal of lowering production costs and increasing market share.

Total project time, from initial consultation to delivery of the components for the first unit, was 12 weeks.

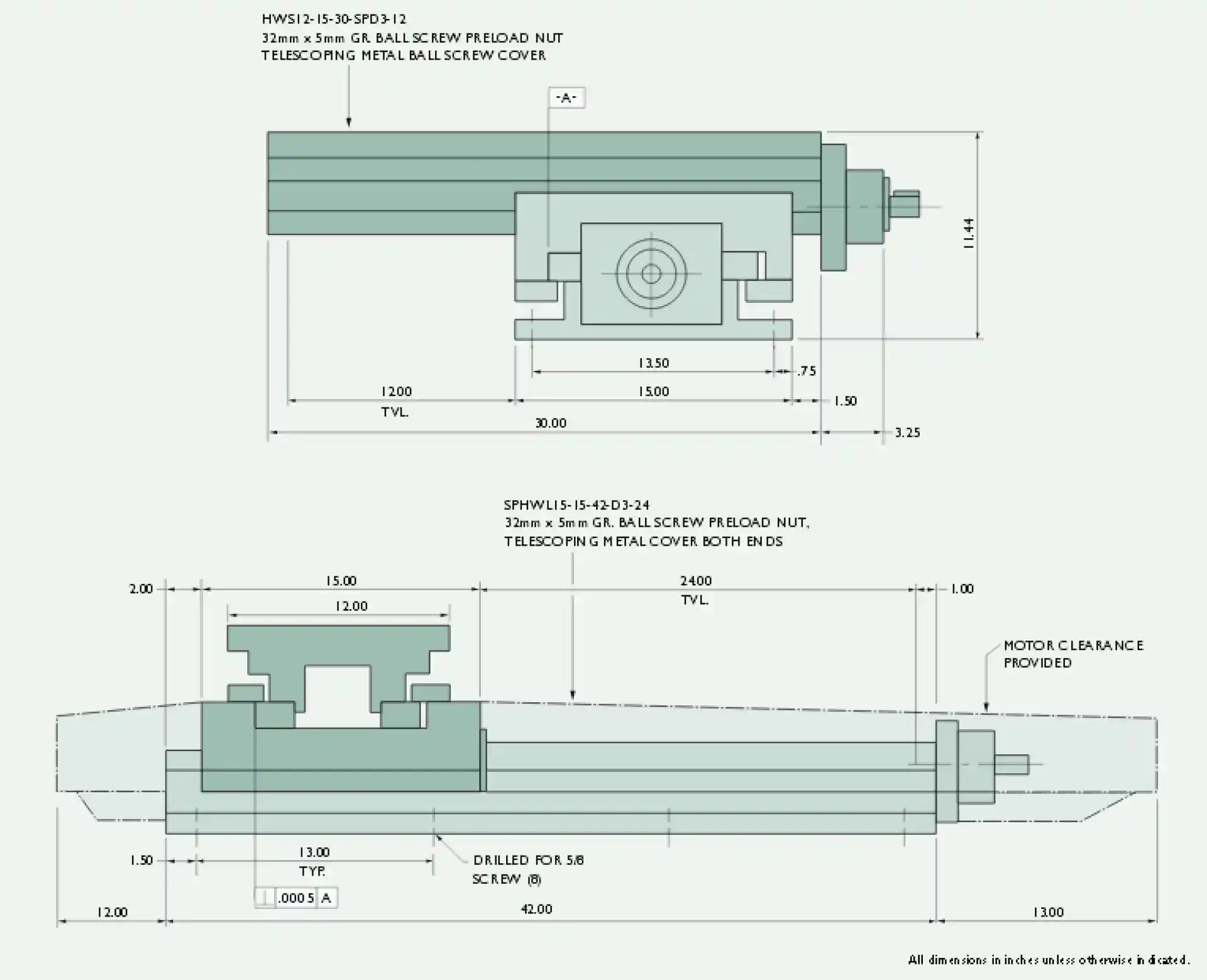

HWS 12-15-30-SPD3-12 Slide:

SPHWL 15-15-42-D3-24 Slide: