Converting their old, manual- setup machining operations, including some machines from the 1940’s, to a computer-controlled modular system, an after-market automotive products manufacturer looked to achieve dramatic reductions in setup times and associated costs. Initially, the company is designing and assembling a 10-station prototype unit with 3-axis modular machining units performing gun drilling, face milling and boring. Once the concept is proven, the company plans to produce three more similar dial machines.

Typically, the company makes runs of 4,000-100,000 oil pump castings in batch runs, then tears down the line and sets up for another run. Two special problems needed to be solved which did not allow for the use of stock components.

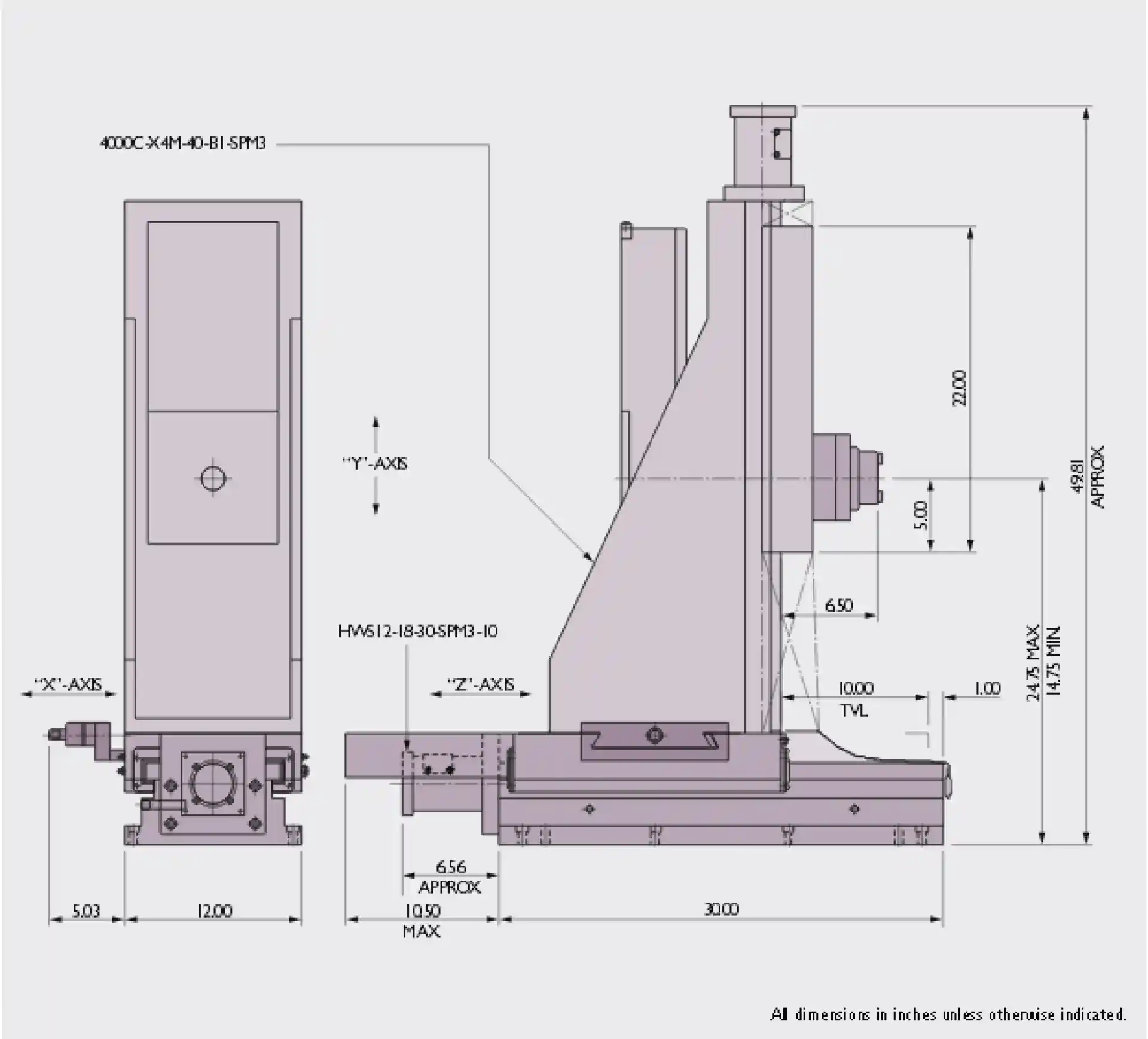

First, the vertical travel of the unit needed to be higher, 10” instead of 6”, and second, the module would require a manually adjustable “X” travel of 2”.

Demonstrating Gilman’s ability to work closely with customers' engineers to realize optimal solutions, both the travel and adjustment requirements were achieved by a single design change. A new casting was designed to accommodate the additional travel and the bottom of the vertical bracket was cast with a male dovetail, while the “Z” axis hardened way saddle was then machined with the complementary female dovetail groove. A manual lead screw drive with a micrometer dial was added, completing the design change. This creative solution delivered the requisite machining travels while eliminating one entire tolerance level (a separate complete slide for the "X" travel).

Setup times that were 40 hours have been reduced to approximately one hour. All machining units are now interchangeable so that if one goes down another unit can be installed quickly. Because all the multi-axis modules employ the same spindle, stocking requirements were reduced from four spindles to one.

Gilman received this competitive bid order after demonstrating their superior response and delivery times. In fact, Gilman’s prototype module was on the customer’s floor before any approval prints had been received from other project bidders.

Spindle:

“Z” Axis Slide: Model No. (HWS12-18-30-SPM3-10)

“Y” Axis Vertical Slide: Model No. (4000C-X4M-40-BI-SPM3)

“X” Axis Adjustment Slide