Non-thrust, machining operations including automotive and aerospace customers.

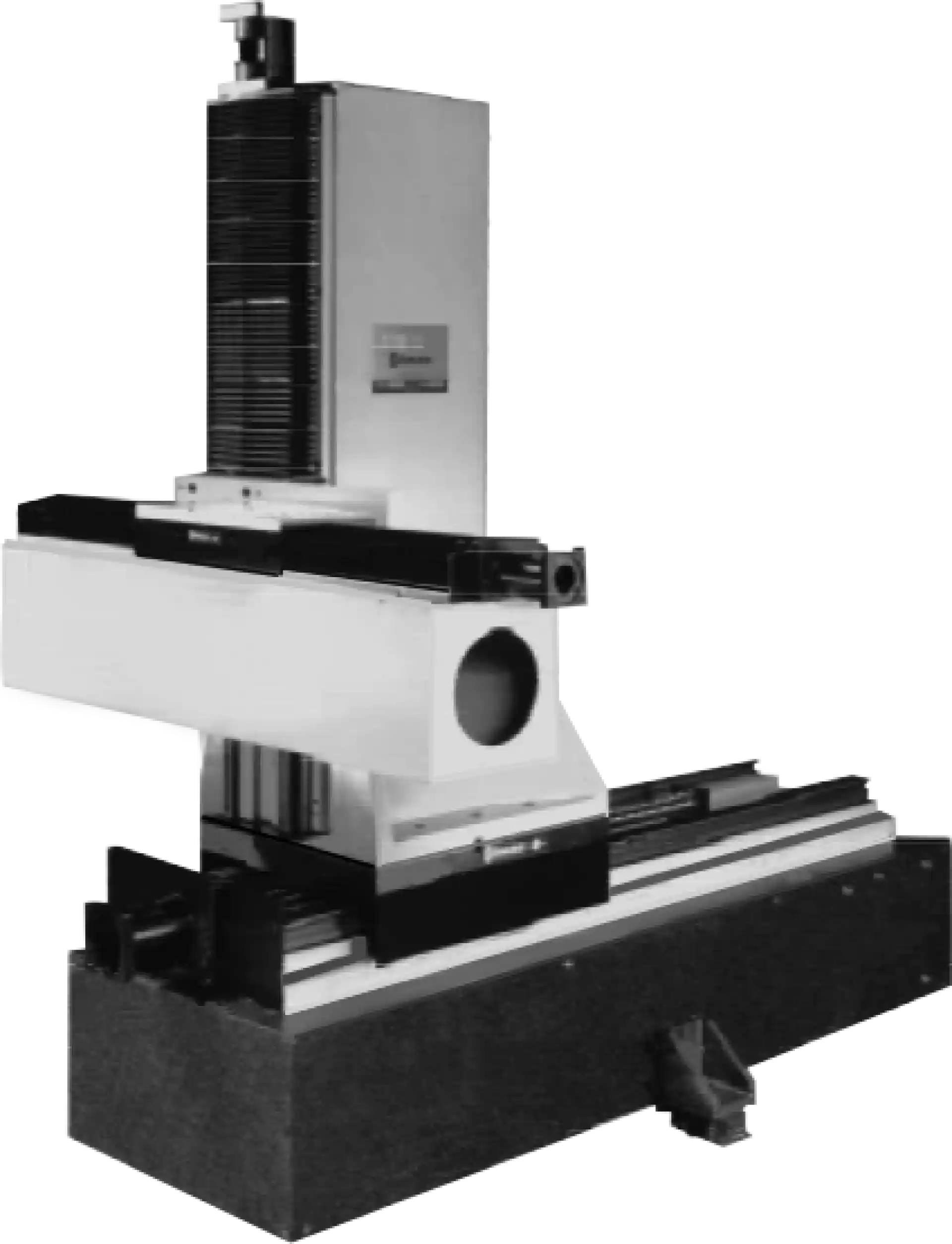

Gilman Precision was given the challenge of developing a 3-axis positioning module for laser-machining operations for an automotive and aerospace customer of an OEM machine builder. The customer had concerns with the previous round-rail slide component’s lightweight construction and structural rigidity.

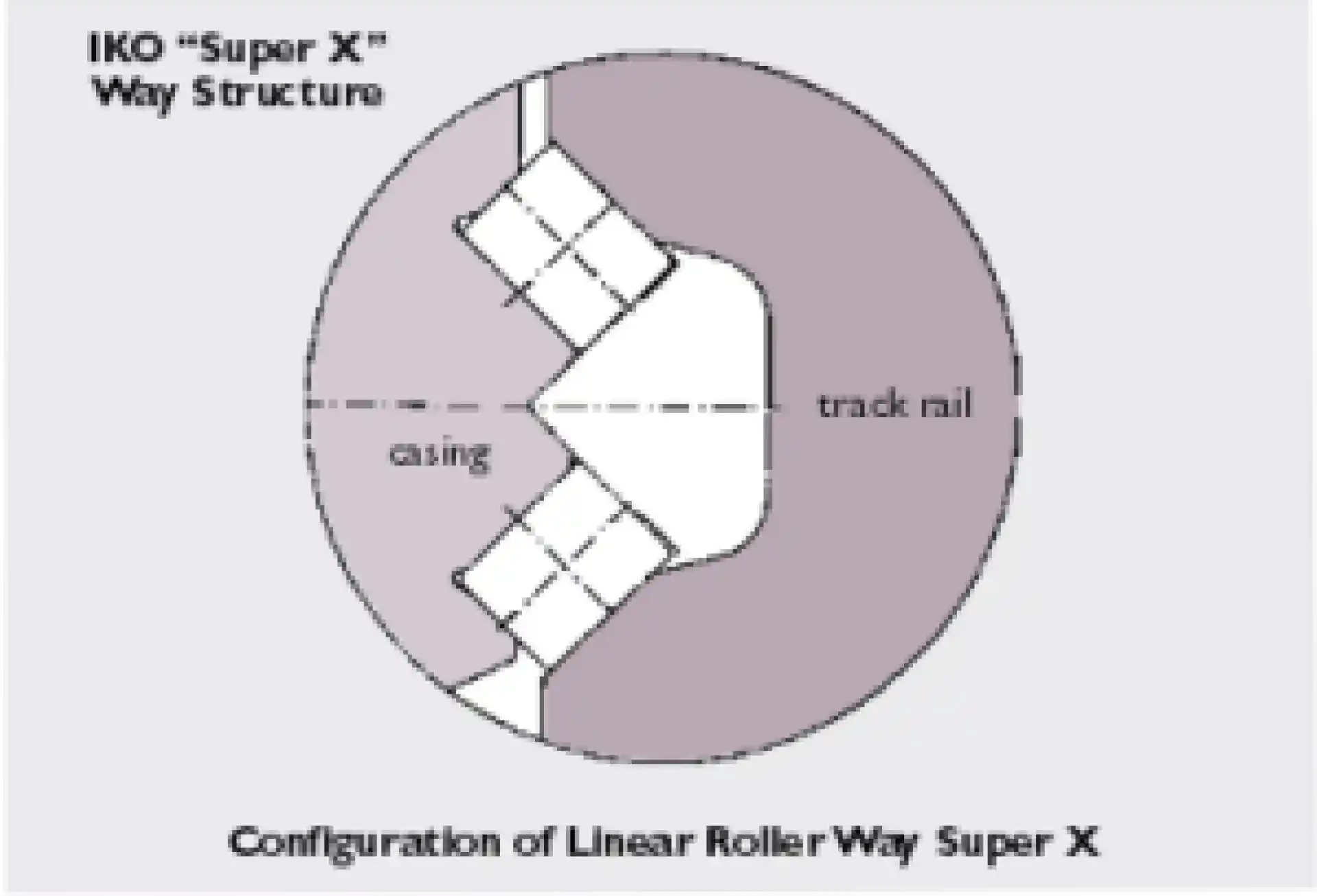

Gilman initiated a partnership with the customer’s engineering team to develop a product that fit their needs: machine-tool-quality rigidity in a 3-axis positioning module. This partnership resulted in a new custom-configured design assembled at Gilman and utilized standard Gilman components. The high degree of rigidity and stability of the final design improved volumetric accuracy by 300%. The ground ball screws used in the 3-axis custom configuration deliver rapid movements at 1000 inches per minute. The carefully selected rail structure for the slide component was a key factor in the success of the project. IKO “Super X” series anti-friction rollers were chosen by Gilman for their high vibration damping characteristics. The recirculating rollers of the “Super X” provide 2.6 times the rigidity of a ball-type guide-way of the same size, supplying accuracy needed for this application.

Continuing the partnership approach, Gilman helped the customer develop a “just- in-time” business plan that delivers the modules on the exact date specified by the customer. Now, with Gilman as an integral part of the business plan, the customer continues to maintain deadlines while maximizing warehouse floor space and increasing overall productivity.

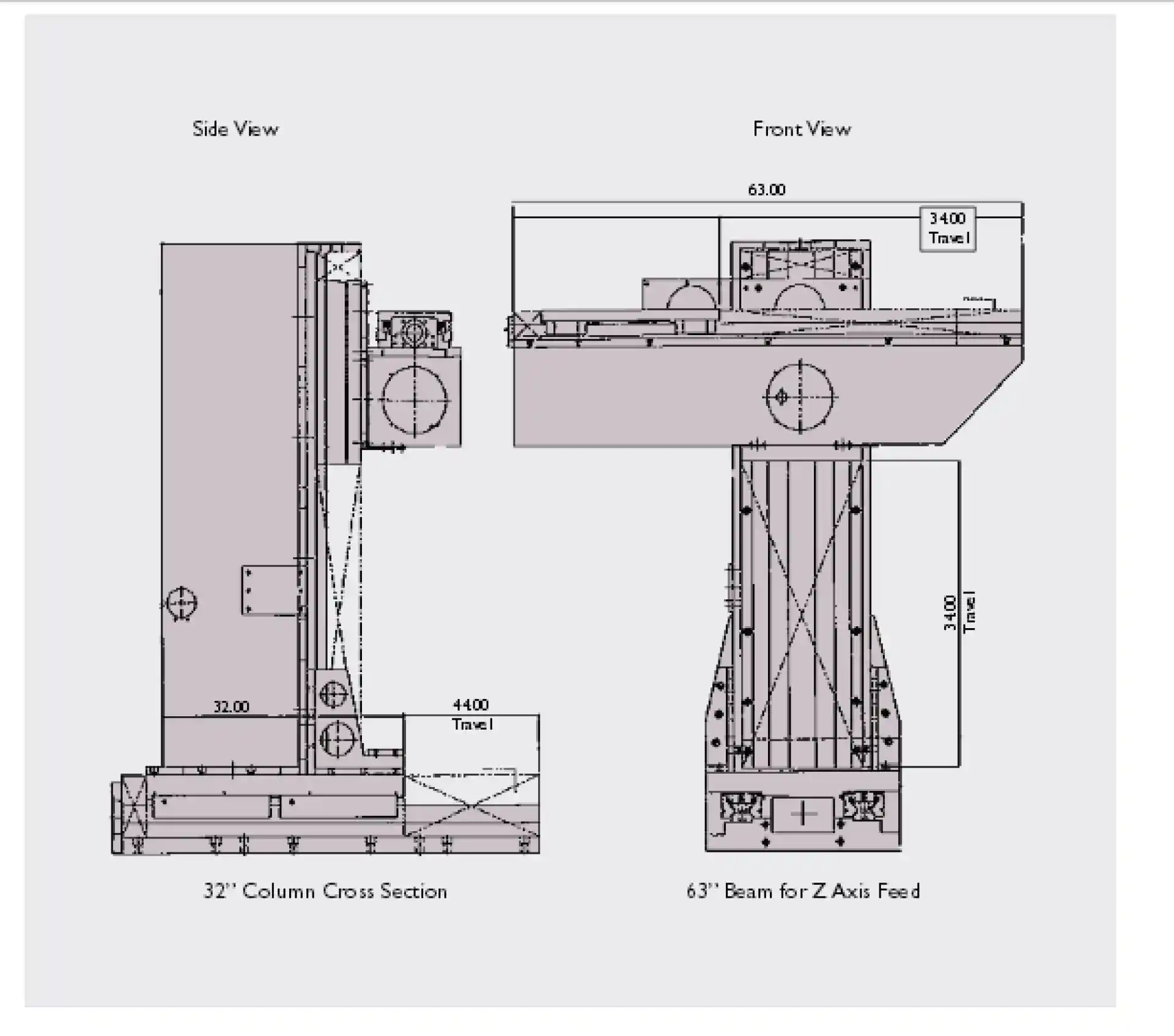

The new module provides movement of:

34” in the Y axis

44” of cross feed

34” of infeed

The IKO “Super X” roller sizes for the design are:

25mm for the Y axis

45mm for the Z axis

65mm for the X axis

Continuing the development of the application, Gilman designed a derivative of the basic design that allows 72” of Y travel for a specific application. The motor mounts and couplers for the Gilman custom-designed, 3-axis positioning module for non- thrust machining operations were provided by Gilman. The customer provided the control package.

Roller Bearing Slide Tolerances

1. Vertical Tracking .0003/axis

2. Horizontal Tracking .0003/ft.axis

3. Perpendicularity .0001

4. Flatness .0005/ft./axis