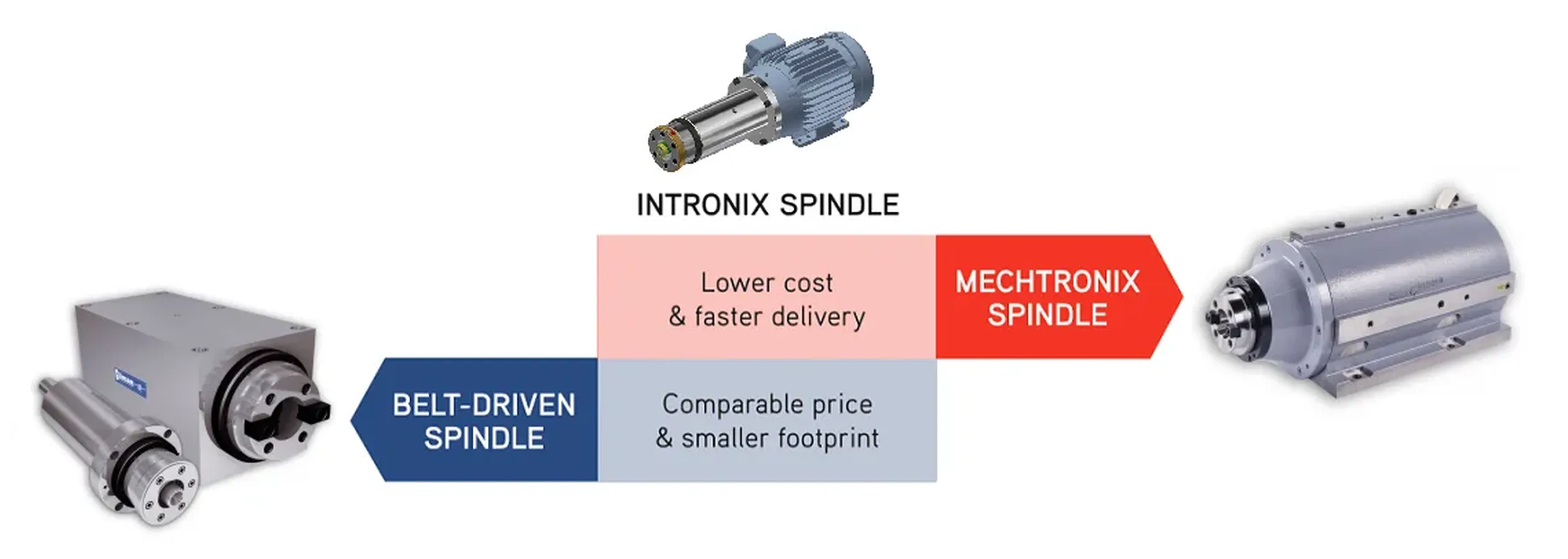

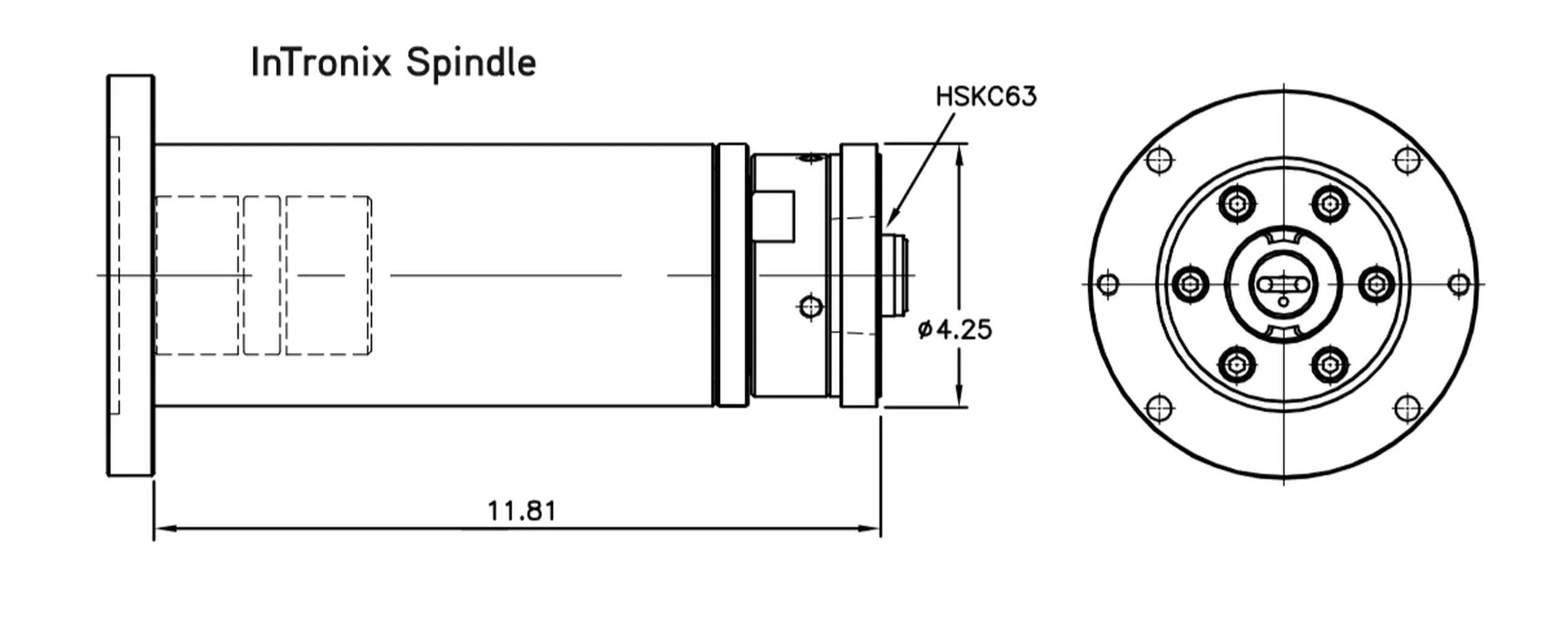

Introducing the newest and most versatile addition to Gilman Precision’s spindle line: the InTronix compact motorized spindle. Combining the benefits of our belt-driven and motorized spindles, the InTronix boasts the ability to direct couple to any motor. The InTronix Spindle is predominantly used for grinding, milling and boring applications, and the featured HSK manual clamp simplifies the process of changing out different tooling options.

Introducing the newest and most versatile addition to Gilman Precision’s spindle line: the InTronix compact motorized spindle. Combining the benefits of our belt-driven and motorized spindles, the InTronix boasts the ability to direct couple to any motor. The InTronix Spindle is predominantly used for grinding, milling and boring applications, and the featured HSK manual clamp simplifies the process of changing out different tooling options.

A major aircraft engine manufacturer wanted to upgrade to a Mech-Tronix spindle on its OM-3 and OM-4 Sundstand Omnimills (5-axis machining centers with a 150-degree tilting head). The material being machined was Inconel, titanium, and other aerospace alloys.